In the hygiene machinery industry, where efficiency and reliability often take center stage, WELLDONE has redefined priorities by placing environmental stewardship at the core of its operations. Through innovative green manufacturing practices, WELLDONE is leading the charge toward a sustainable future while maintaining its reputation for high-quality, cutting-edge machinery.

The Vision for Green Manufacturing

At WELLDONE, green manufacturing is more than a strategy; it’s a vision that aligns with the growing global demand for sustainable practices. This vision is deeply rooted in three pillars: resource conservation, eco-friendly innovation, and industry leadership.

- Resource Conservation: Prioritizing the reduction of natural resource usage at every production stage.

- Eco-Friendly Innovation: Developing technologies that minimize environmental impact without sacrificing performance.

- Industry Leadership: Inspiring change across the sector by demonstrating the viability of sustainable practices.

Sustainable Material Selection

WELLDONE’s commitment to green manufacturing begins with a careful selection of materials. By prioritizing renewable, recycled, and ethically sourced components, the company significantly reduces its environmental footprint.

- Recycled Metals: High-grade recycled alloys are used for key components, reducing reliance on virgin raw materials.

- Bioplastics: Durable and biodegradable polymers replace traditional plastics in machine designs.

- Ethical Sourcing: The company collaborates with suppliers who adhere to rigorous environmental and social responsibility standards.

Energy-Efficient Production Processes

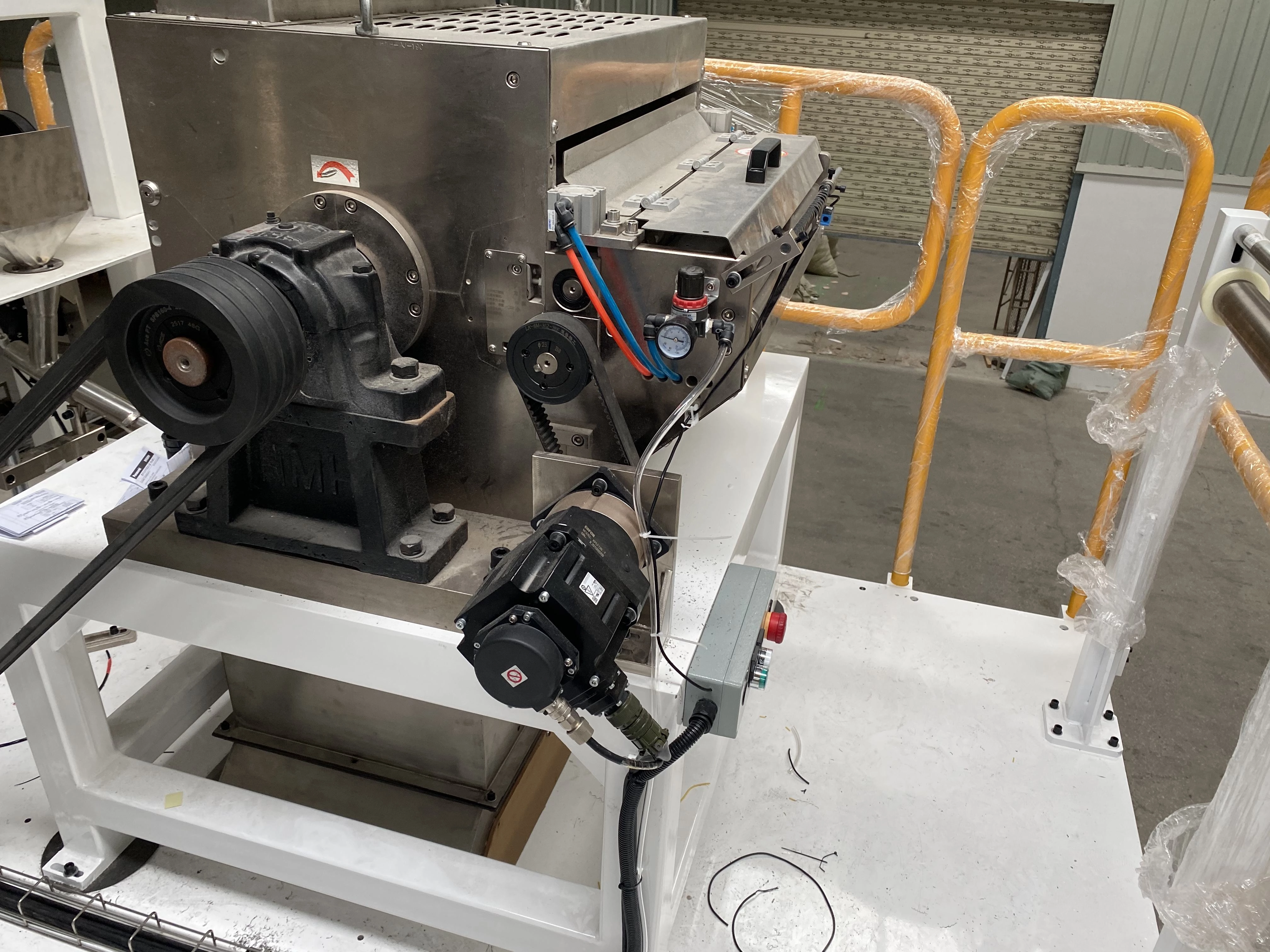

A hallmark of WELLDONE’s approach is its energy-efficient manufacturing processes, designed to conserve power while optimizing productivity.

- Smart Manufacturing Systems: Advanced IoT technology monitors and optimizes energy usage in real-time.

- Low-Energy Equipment: Cutting-edge machinery consumes less power during operation, lowering production emissions.

- Renewable Energy: Solar panels and wind energy sources provide clean electricity to WELLDONE’s facilities.

Innovations in Eco-Friendly Machinery

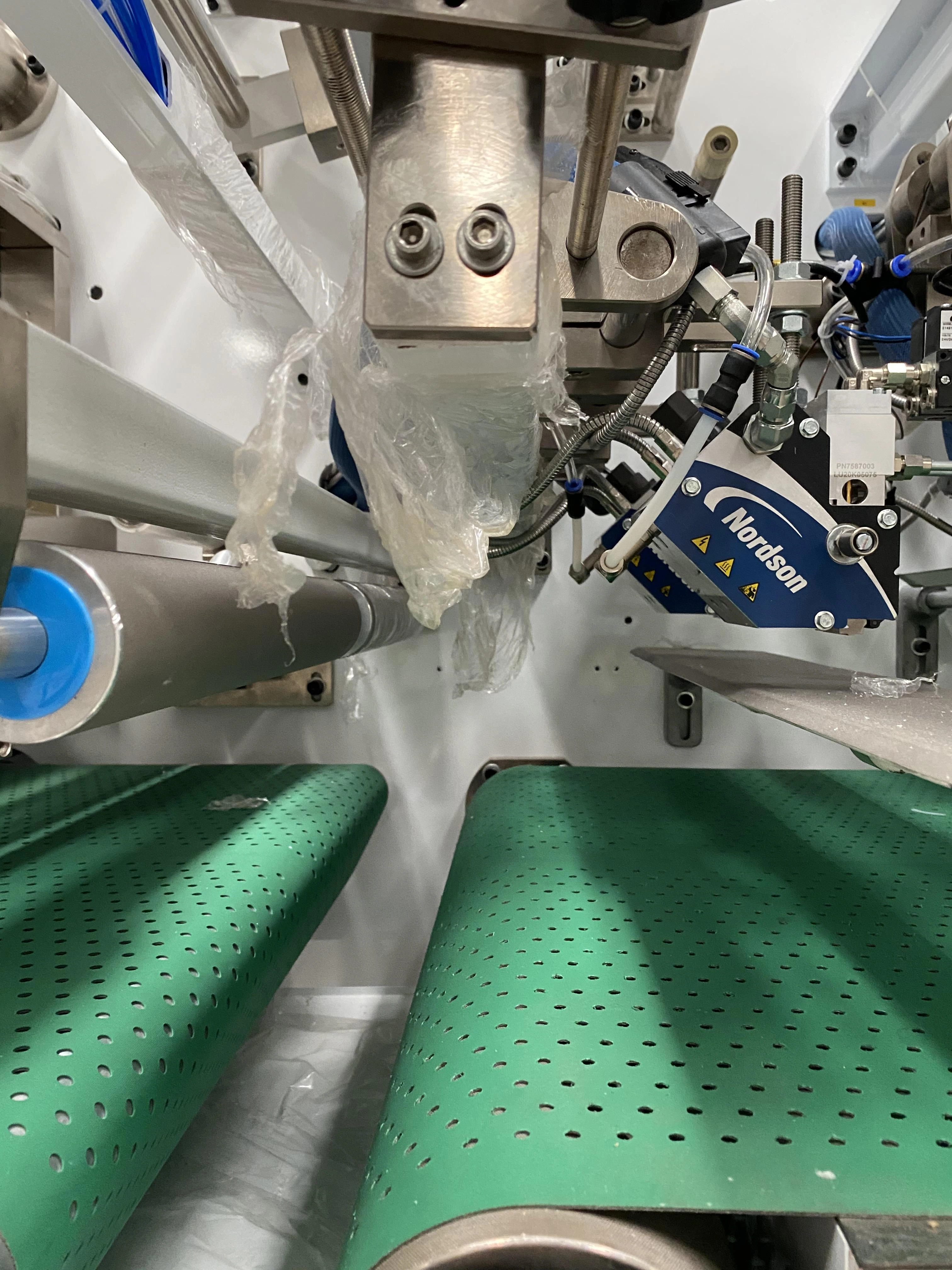

WELLDONE’s machines are engineered to integrate green principles into their functionality. Each design focuses on efficiency, durability, and minimal environmental impact.

- Energy Optimization: Machines use intelligent systems to adjust power consumption based on workload.

- Minimal Waste: Designs ensure fewer byproducts during manufacturing and operation.

- Longevity: Extended machine lifespans reduce the need for frequent replacements, cutting down waste.

Waste Management and Recycling Initiatives

To complement its energy-saving measures, WELLDONE has implemented an industry-leading waste management program.

- Circular Production Model: Scrap metals and materials are repurposed into new components, reducing waste.

- Eco-Friendly Disposal: Unusable waste is processed in compliance with the highest environmental standards.

- Biodegradable Packaging: Shipping materials are designed to decompose naturally, minimizing landfill contribution.

Industry Collaboration for Sustainability

WELLDONE actively collaborates with industry partners, governments, and environmental organizations to drive sustainable practices across the hygiene machinery sector.

- Green Partnerships: The company works with suppliers and distributors committed to sustainability.

- Educational Outreach: WELLDONE shares its green manufacturing expertise with clients and industry peers.

- Regulatory Advocacy: By engaging with policymakers, the company helps shape regulations that encourage eco-friendly manufacturing.

Certifications and Recognitions

WELLDONE’s environmental initiatives are validated by globally recognized certifications and accolades.

- ISO 14001 Certification: Acknowledging WELLDONE’s robust environmental management systems.

- Carbon Footprint Reduction Awards: Recognizing tangible results in emission cuts.

- Sustainable Manufacturing Accolades: Highlighting leadership in green production methods.

Challenges and Continuous Improvement

While WELLDONE has achieved significant milestones in green manufacturing, the journey toward sustainability is ongoing.

- Balancing Costs and Sustainability: The company continuously works to make green practices economically viable.

- Scaling Innovations: Expanding sustainable technologies across all product lines remains a key focus.

- Global Impact Goals: WELLDONE is committed to achieving net-zero emissions and zero waste by 2035.

A Sustainable Future with WELLDONE

WELLDONE’s dedication to green manufacturing exemplifies how the hygiene machinery industry can embrace sustainability without compromising on quality or innovation. By adopting eco-friendly materials, energy-efficient processes, and waste management systems, the company sets an inspiring example for its peers.

Choosing WELLDONE means more than investing in superior machinery—it’s a commitment to supporting sustainable practices and contributing to a greener future. Together with its clients, WELLDONE is forging a path where productivity and environmental responsibility are not just compatible but inseparable.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.