In 2024, when the global market size of medical-grade hygiene products exceeded 38 billion US dollars, compliant manufacturing has become the core battlefield of brand competition. From the biocompatibility testing of medical sanitary napkins to the aseptic process of postoperative care pads, WELLDONE, with the dual advantages of "medical-grade standards + local response", helps brands break through the access barriers of more than 50 markets such as Europe, America, and Southeast Asia, and seize strategic opportunities in the wave of compliance. Today, we will talk about the ISO 13485 certification regarding the upgrade of the OEM standards for medical-grade hygiene products.

The Explosion of the Medical-grade Hygiene Products Market: Compliance and Safety Become the Core Competitive Points

With the improvement of global health awareness and the expansion of medical scenarios, hygiene products are upgrading from "daily consumption" to "medical assistance" attributes. According to data from Grand View Research, the global market size of medical-grade hygiene products is expected to reach 38 billion US dollars in 2024, with a compound annual growth rate of over 9%. Among them, the demand for sub-categories such as medical sanitary napkins, postoperative care pads, and incontinence management products has surged, pushing brand owners to put forward higher requirements for OEM production: The ISO 13485 Medical Device Quality Management System Certification has become a "hard threshold" for cross-border cooperation.

As a leading enterprise that has been deeply engaged in the OEM field of hygiene products for 15 years, WELLDONE has observed that: The ISO 13485 certification has been listed as a mandatory standard for government procurement and retail channels in mainstream European and American markets. And if Asian brands want to break through regional limitations and participate in global competition, they must obtain this international pass.

ISO 13485 Certification: Three Driving Factors from "Bonus Item" to "Necessary Option"

-

Accelerated Penetration of Medical Scenarios

-

Reconstruction of Consumer Trust

Global surveys show that 68% of consumers are willing to pay a 15%-20% premium for "medical-grade certified" products. WELLDONE's cooperation cases show that for brands with ISO 13485 certification, the access cycle in the Japanese and German markets has been shortened by 40%, and the repurchase rate has increased by 25%.

-

Forced by the Compliance Cost of the Supply Chain

Non-compliant products face the risk of high fines: The US FDA can impose a maximum fine of 500,000 US dollars per violation on enterprises, and the return rate in the EU market may be as high as 30%. Through the certification, WELLDONE has reduced the quality risk cost by 60%, helping brands achieve long-term benefits.

WELLDONE's Practical Experience: The "Triple Upgrade" Behind the ISO 13485 Certification

As one of the first enterprises in the Jinjiang hygiene products industrial cluster to pass the ISO 13485:2016 certification, WELLDONE has established a full-link compliance system:

-

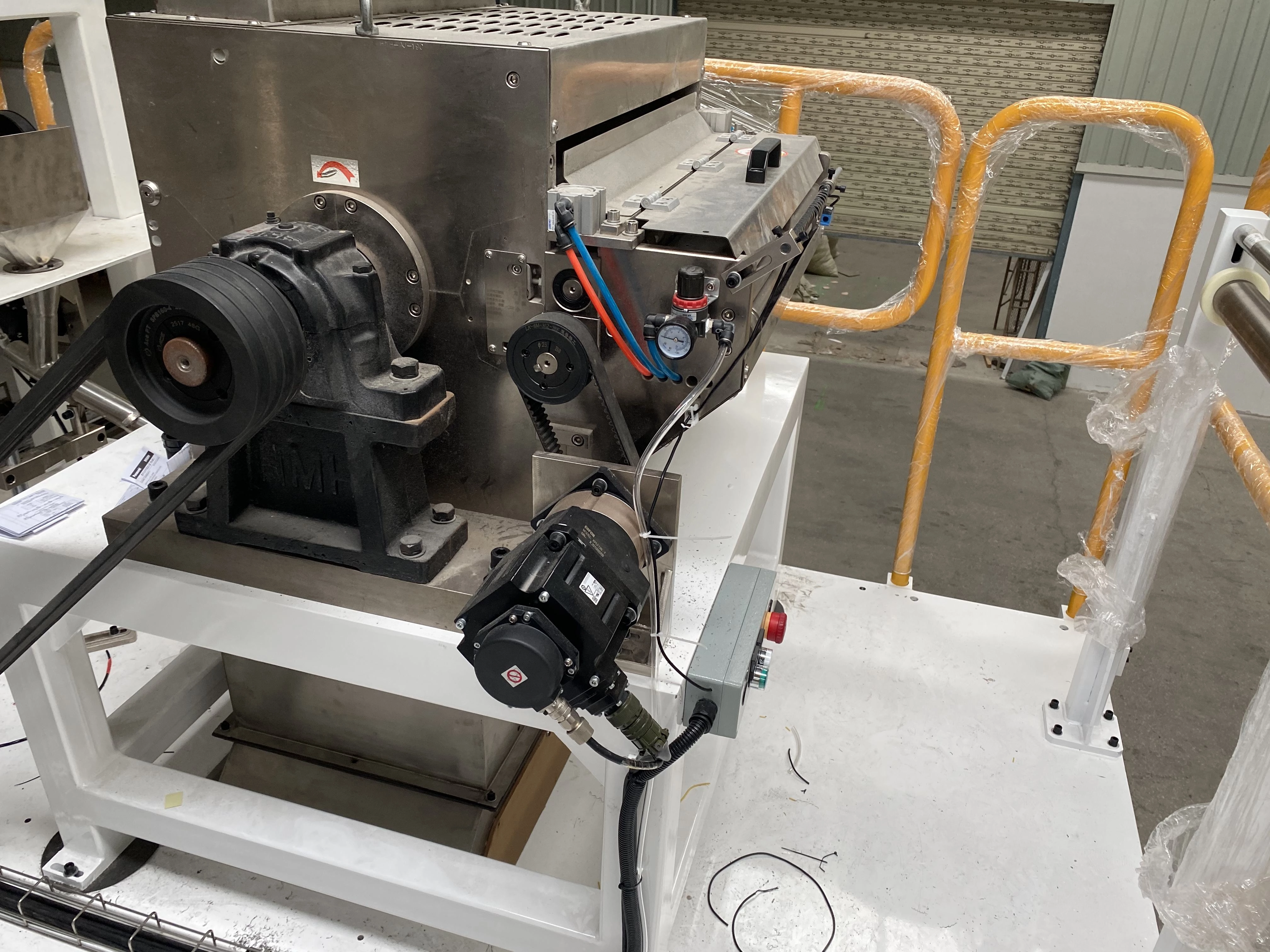

Upgrade of Hardware Facilities

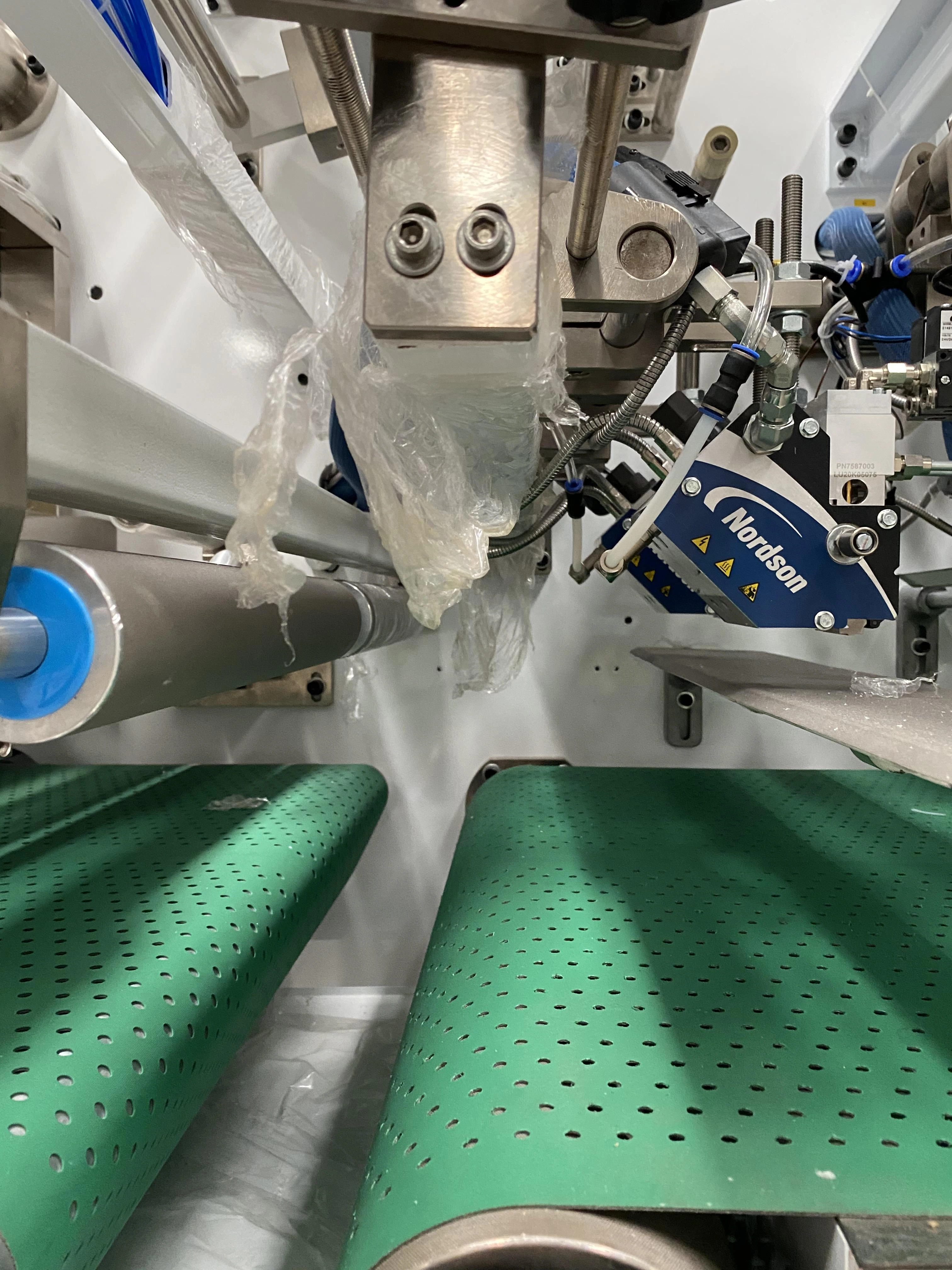

Invested tens of millions of yuan to build a 100,000-class dust-free workshop, equipped with an online microbial detection system.

Introduced German KCA high-speed production lines to achieve full-process closed-loop control from raw materials to finished products.

-

Reconstruction of the Quality Management System

Established a "dual-track" traceability system: The tracking accuracy of raw material batches reaches 0.1g, and the flow of finished products can be traced back to specific medical institutions.

Implemented the FDA 21 CFR Part 11 electronic record specification to ensure that the data cannot be tampered with.

-

Compliance of Technological Innovation

Developed an SAP composite core that has passed the biocompatibility test (the cytotoxicity test result is ≤ 0.5 level).

Launched a degradable non-woven fabric solution, which complies with the EU EN 13432 composting standard.

The "Golden Triangle" Evaluation Model for Brands to Select OEM Factories

Based on 15 years of experience in serving international brands such as Unilever and Unicharm, WELLDONE has proposed a B2B cooperation evaluation framework:

|

Evaluation Dimension |

Industry Standard |

WELLDONE's Advantages |

|

Compliance Ability |

ISO 13485 + CE/FDA |

Five-country certification system (including Saudi SFDA and Brazilian ANVISA) |

|

Technical Reserve |

Conventional Production Capacity |

Customized development of medical-grade products (such as antibacterial coating technology) |

|

Response Speed |

60-day Delivery Cycle |

30-day rapid prototyping + modular production capacity allocation |

Typical case: A certain European medical group, through WELLDONE's "medical-grade customization solution" (https://www.cnwelldone.net/solution), has compressed the access time of its products in the EU market from 9 months to 4 months, and the order volume in the first year exceeded 12 million pieces.

Trend Prediction for 2025: The Medical-grade OEM Industry Enters the Era of "Precise Compliance"

-

Deepening of Sub-scenarios

-

Integration of ESG and Compliance

-

Differentiation of Regional Standards

About WELLDONE

Choosing a Compliant Partner Means Choosing Market Competitiveness

In the field of medical-grade hygiene products, compliance is no longer just a "cost investment", but also a strategic weapon for brands to break through the situation. With the ISO 13485 certification system and 15 years of industry accumulation, WELLDONE provides global brands with full-chain support from raw material research and development, process design to international certification.

Visit our solution immediately to obtain the "Compliance Guide for OEM of Medical-grade Hygiene Products" and seize the market opportunities in 2025!

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.