Sanitary products OEM factory: practical strategies to reduce brand owners' inventory pressure by 30%

In the global sanitary products market, the inventory pressure faced by brands is becoming a key bottleneck restricting development. Data shows that due to the characteristics of large demand fluctuations and fixed production cycles in the sanitary products industry, the average inventory turnover rate of brands is only 4 times/year, and the proportion of unsalable inventory is as high as 20%, and a large amount of funds are accumulated. As a sanitary napkin raw material and machinery OEM factory with 15 years of deep cultivation in the industry, WELLDONE is well aware of the importance of inventory optimization to brand owners' profit improvement. Based on the practical experience of serving the global market, this article summarizes a set of inventory decompression solutions suitable for the sanitary products industry to help brands break through inventory difficulties and improve supply chain efficiency.

1. Three sources of inventory pressure in the sanitary products industry

The special properties of sanitary products determine the complexity of inventory management. First, there are seasonal fluctuations in demand for products such as sanitary napkins. For example, sales surge during e-commerce promotions. Under the traditional OEM model, brands need to prepare stocks three months in advance, which can easily lead to inventory backlogs in the off-season. Secondly, the raw material procurement cycle is long, and the international supply chain fluctuations of core raw materials such as fluff pulp and polymer absorbent resin may cause production interruptions, forcing brands to overstock raw materials. Finally, with the increase in small-batch customized orders, brands are often forced to increase safety stocks due to insufficient flexibility of OEM factories to meet diversified needs.

2. WELLDONE's inventory optimization solution: Solve the inventory dilemma from the production end

2-1. Flexible production scheduling system

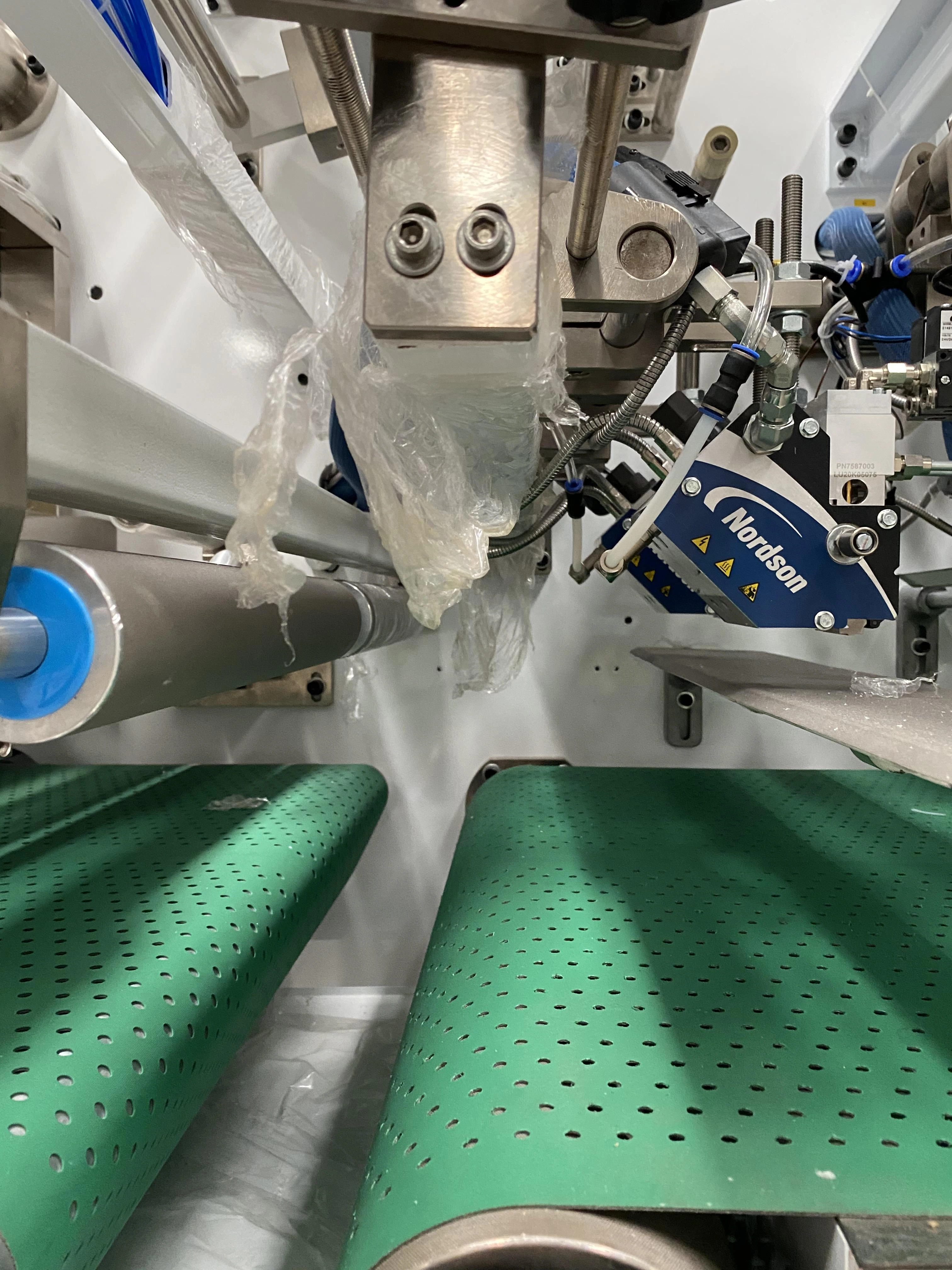

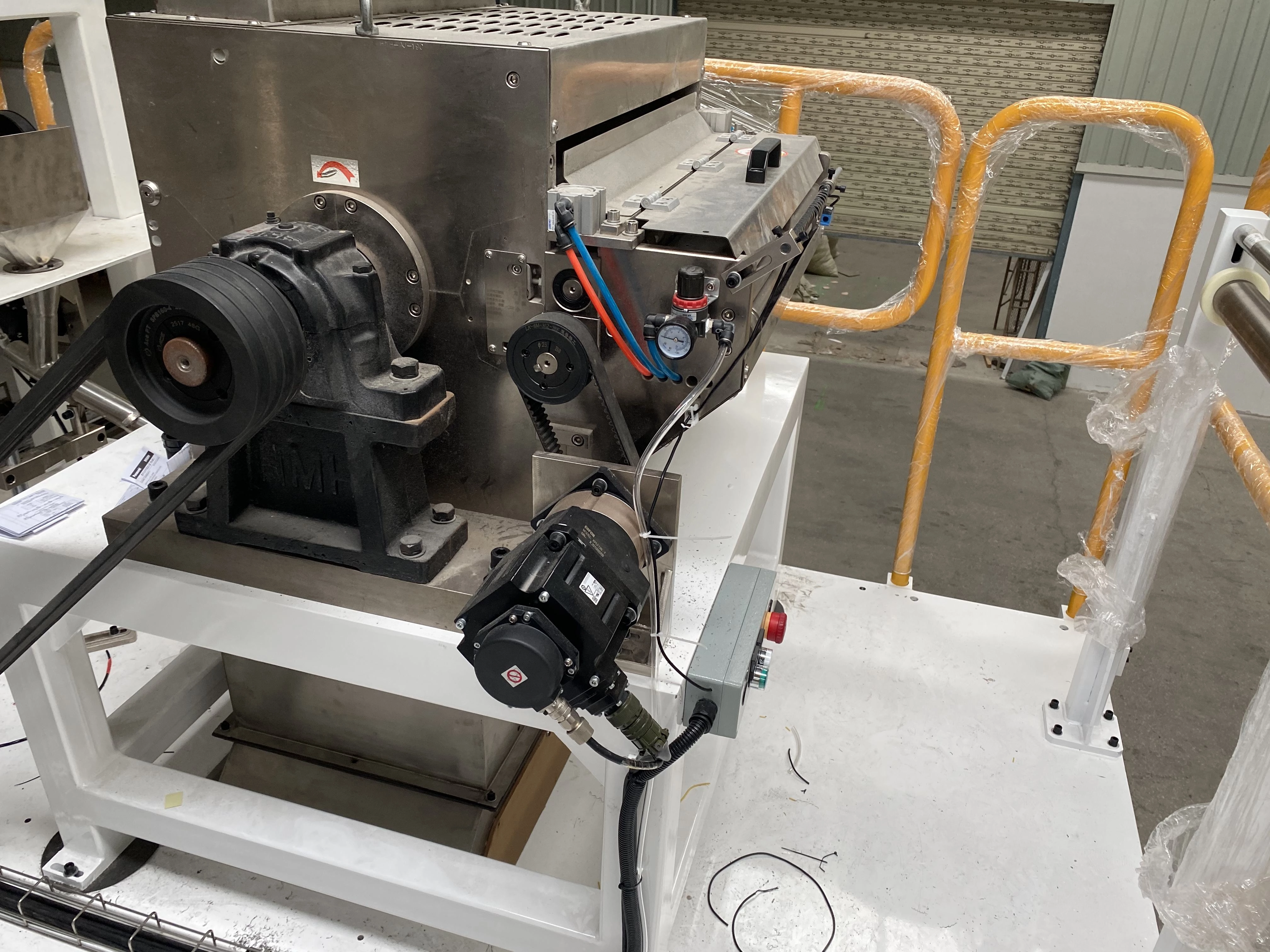

Relying on 15 years of production experience, WELLDONE has established a flexible production model of "multiple batches and small batches". In view of the characteristics of sanitary napkin machinery OEM, a modular production line design is adopted to achieve 4-hour rapid switching of products of different specifications, which shortens the switching time by 60% compared with the industry average. This means that brands can place orders in batches according to market demand, and the minimum order quantity is reduced to 50% of the industry's conventional standard, without the need to overproduce to meet the order quantity.

2-2. Strategic reserve mechanism for core raw materials

As a foundry that has been deeply involved in the global market, WELLDONE has set up a raw material reserve warehouse that can accommodate 30 days of consumption at its Jinjiang base in Fujian, focusing on 12 core raw materials such as fluff pulp and breathable bottom film. By signing long-term agreements with international suppliers, the raw material prices and supply cycles are locked in, ensuring the stability of raw material supply for emergency orders from brands, and reducing the brand's own raw material inventory demand by 40%.

2-3. 72-hour expedited order response mechanism

In response to sudden demands in the sanitary products industry (such as emergency epidemic prevention material supporting orders), WELLDONE has optimized the order processing process: from the brand's order to the production schedule confirmation, it takes no more than 8 hours, and conventional specification products are completed and delivered within 72 hours, which is significantly shorter than the industry average of 10 days. After the cooperation, a Southeast Asian brand reduced its safety inventory level by 32% and its annual inventory cost by 2.8 million yuan due to the improved response speed of emergency orders.

3. Practical value: from cost control to market competitiveness improvement

The core value of inventory optimization is not only to reduce storage costs, but also to release funds for brand operations. According to the data of European customers served by WELLDONE, after the cooperation, its inventory turnover rate increased from 3.8 times/year to 5.2 times/year, capital turnover efficiency increased by 36%, and new product R&D investment increased by 15%. In addition, through the flexible support of the OEM side, brands can more flexibly launch Private label customized products, quickly test market feedback, and reduce trial and error costs.

Important keywords in the industry: inventory optimization, flexible supply chain, sanitary products OEM, order response speed, supply chain collaboration

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.