Why Focus on the Production Line of Medical-grade Sanitary Napkins?

At present, with the global market size of medical-grade hygiene products exceeding 38 billion US dollars, medical-grade sanitary napkins, as essential products for scenarios such as postoperative care and chronic disease management, are undergoing unprecedentedly strict scrutiny of their production standards. When international brands select OEM partners, they are no longer limited to basic production capacity but instead focus on the ability to comprehensively control "medical-grade safety" throughout the process. As a leading enterprise in the Jinjiang hygiene products industrial cluster in China, WELLDONE, with 15 years of in-depth experience, provides "zero-defect" solutions from raw materials to finished products for international customers such as Johnson & Johnson and Pfizer through 10 core quality inspection procedures and the ISO 13485 certification system. This article will deeply analyze the production secrets of medical-grade sanitary napkins and reveal how leading OEM factories use their technical strength and compliance systems to help brands seize the market high ground. Unveiling the Production Line of Medical-grade Sanitary Napkins - the OEM Strength Behind 10 Quality Inspection Procedures

The Explosion of the Medical-grade Sanitary Napkin Market: Safety and Compliance Become the Core Competitive Points

Driving Factors of the Surge in Demand

- There are approximately 28 million gynecological surgeries globally each year. For every 1% reduction in the postoperative infection rate, 35,000 lives can be saved (WHO data).

- The large population of diabetic patients has led to an annual growth rate of 12% in the market for their specialized care products, posing extremely high requirements for the safety of materials.

Challenges Brought by International Standards

- The EU's MDR regulations require medical sanitary napkins to pass biocompatibility tests (ISO 10993) and cytotoxicity assessments.

- The US FDA includes medical-grade products in the 510(k) pre-market notification process, with a review cycle of up to 6 to 9 months.

WELLDONE's Practice: Through the ISO 13485 certification, the product's access cycle in the EU market has been shortened by 40%, and the customer return rate is less than 0.3%.

10 Core Quality Inspection Procedures of the Production Line of Medical-grade Sanitary Napkins

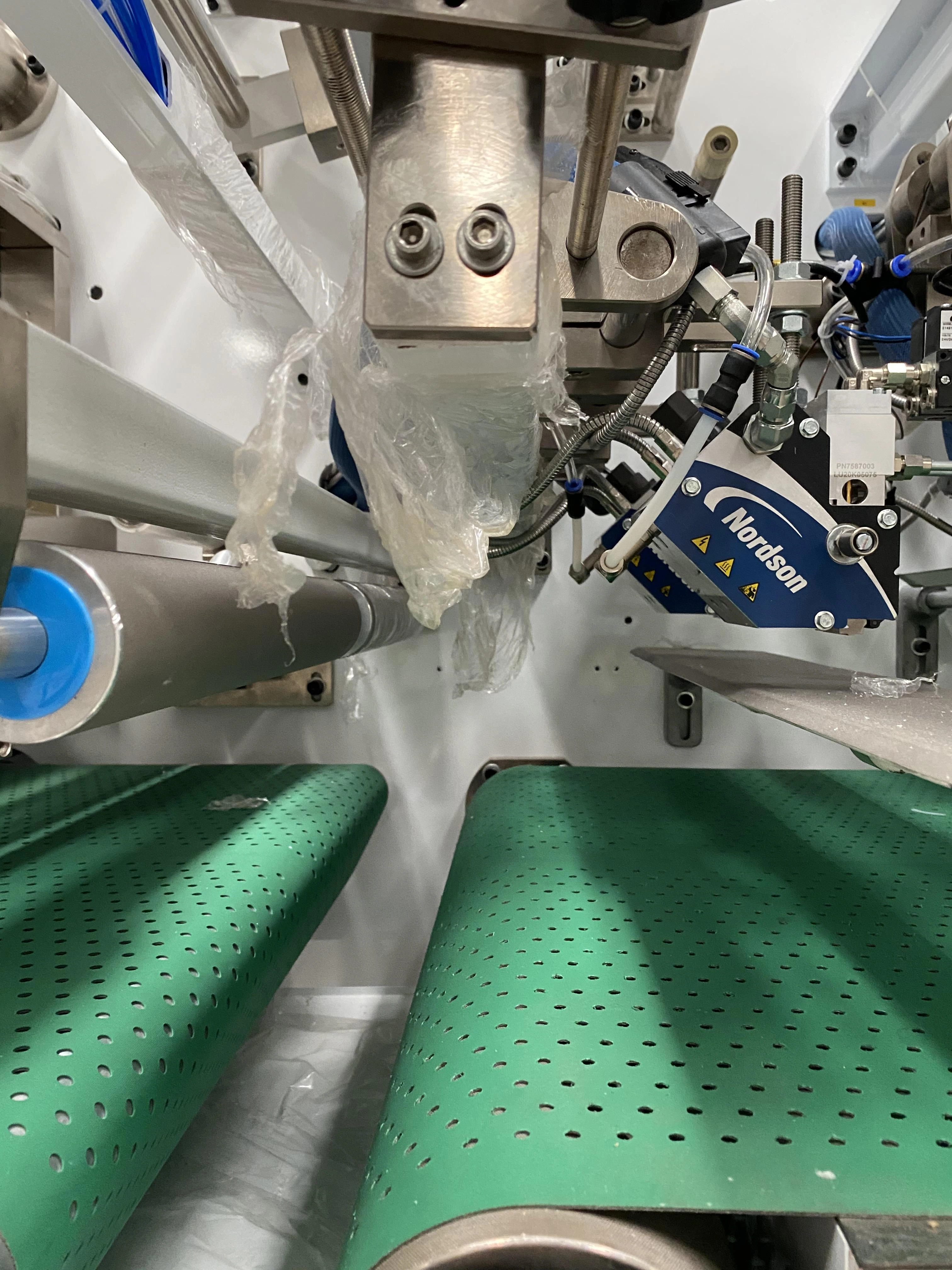

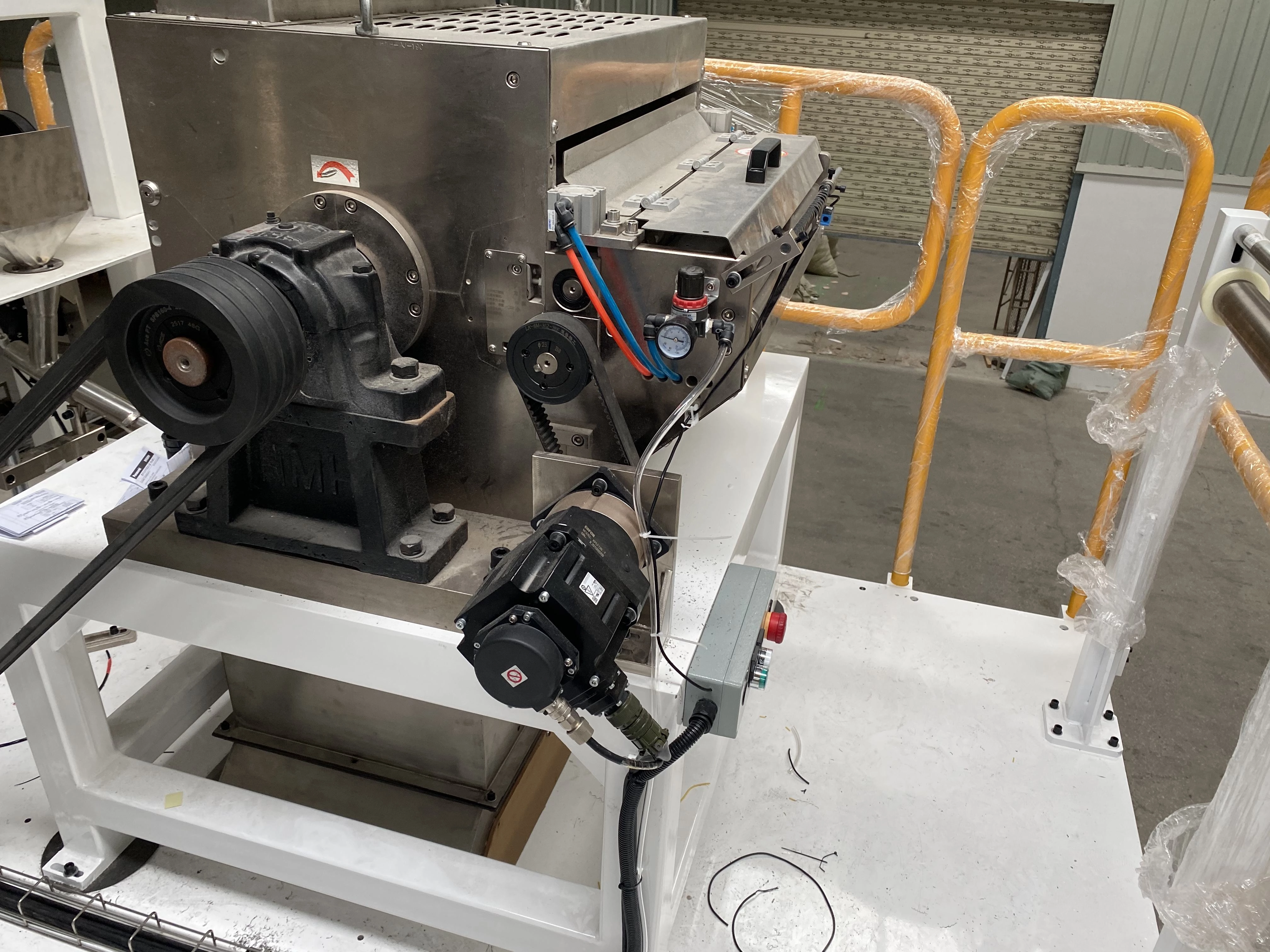

Relying on the German KCA high-speed production line and its independently developed quality control system, WELLDONE has established a "medical-grade safety network" covering the entire process:

Raw Material Traceability (Batch Tracking)

- Record the supplier information of each batch of SAP resin and non-woven fabric.

- Sample and test each 100kg of raw materials for heavy metal content (standard: ≤ 0.01ppm).

Cleanroom Control

- The 100,000-class dust-free workshop is equipped with a differential pressure monitoring system to ensure that the number of air dust particles ≤ 352,000 pieces/m³.

- Operators need to go through 7 purification procedures (including air shower, ultraviolet disinfection, etc.) before entering the production area.

In-process QC

- Core Thickness Detection: The laser scanning accuracy reaches 0.01mm to ensure the uniformity of the absorption layer.

- Sealing Strength Test: Use a smart pressure sensor to detect the edge peeling force of each product (standard: ≥ 1.5N/cm).

Microbial Limit

- The online microbial detection system monitors the production environment in real time, with the total number of bacterial colonies ≤ 100CFU/g.

- Conduct ethylene oxide residue detection before the finished product leaves the factory (standard: ≤ 10μg/g).

Technical Highlights: The independently developed "double-core structure" has passed the SGS certification, with an absorption speed 20% faster than traditional products, and it has also passed the 100,000-time friction test without damage.

Three OEM Advantages of WELLDONE: From Compliance to Innovation

Full-chain Compliance Ability

- Hold 8-country certifications such as FDA, CE, and ISO 13485, supporting product exports to more than 50 markets globally.

- Establish a "compliance database" to automatically update changes in regulations of various countries (such as the EU SUPD 2.0 Single-use Plastics Directive).

Customized R&D Strength

- Develop the "antibacterial coating technology" (silver ion loading ≤ 0.5%), with an antibacterial rate > 99.9% as detected by a third party.

- Provide an environmentally friendly solution of "degradable non-woven fabric + corn starch-based back film", which has passed the OK Compost industrial composting certification.

Agile Response Mechanism

- Equipped with 3 rapid prototyping lines, which can deliver customized samples within 72 hours.

- The peak-season production capacity flexible allocation system supports a rapid response to order volume fluctuations of ± 30%.

Customer Case: A certain Japanese medical group, through WELLDONE's "aseptic process optimization solution", shortened the registration time of its products with the Japanese Ministry of Health, Labour and Welfare to 3 months, and the order volume in the first year exceeded 8 million pieces.

The "Four-quadrant Evaluation Method" for Brands to Select OEM Factories

Based on its experience in serving international brands, WELLDONE has proposed a B2B cooperation evaluation model:|

Evaluation Dimension |

Basic Requirements |

Industry Benchmark Standards |

|

Compliance System |

ISO 9001 |

ISO 13485 + Regional Certification (such as ANVISA) |

|

Production Precision |

±0.5mm Tolerance |

±0.1mm Laser Calibration |

|

Environmental Protection Ability |

Ordinary Recycling System |

Proportion of Degradable Materials ≥ 30% |

|

Data Transparency |

Monthly Report |

Real-time Production Data Dashboard (MES System Integration) |

Trends in 2025: The Medical-grade OEM Industry Enters the Era of "Scenario-based Customization"

Deepening of Sub-scenarios

- Sanitary napkins specially designed for chemotherapy patients (need to pass the USP 88-level bioreaction test).

- Postpartum repair products (integrated with pH value monitoring function).

Technological Integration and Innovation

- Application of nanofiber membranes (breathability increased by 50% while maintaining a bacterial filtration efficiency > 99%).

- Smart packaging technology (thermosensitive color-changing labels to prompt the opening status of products).

Differentiation of Regional Standards

- The Middle East market requires Halal certification, and Southeast Asia needs to comply with the ASEAN MDSAP system.

Choosing WELLDONE Means Choosing Medical-grade Safety Assurance

In the field of medical-grade hygiene products, product safety is directly related to brand reputation and patient health. Relying on 15 years of technical accumulation and a medical-grade production line, WELLDONE provides global brands with full-chain support from raw material control to international certification. Whether it is the high safety requirements for postoperative care or the customized scenarios for chronic disease management, WELLDONE can empower brands with "10 quality inspection procedures + 360° compliance services".

Visit solution immediately to obtain the White Paper on the OEM of Medical-grade Sanitary Napkins and jointly explore the global medical and health market with WELLDONE!

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.