中文

Русский

español

Home

Media Center

Industry News

Where is the Future of Sanitary Napkin Machinery and Equipment Headed?

Where is the Future of Sanitary Napkin Machinery and Equipment Headed?

The sanitary napkin industry is constantly evolving, and at the heart of this evolution lies the development of sanitary napkin machinery and equipment. As a leading provider of hygiene products and raw materials, WellDone is at the forefront of shaping the future of this essential sector.

WELLDONE

Sep 05

, 22

274 Views

The sanitary napkin industry is constantly evolving, and at the heart of this evolution lies the development of sanitary napkin machinery and equipment. As a leading provider of hygiene products and raw materials, WellDone is at the forefront of shaping the future of this essential sector.

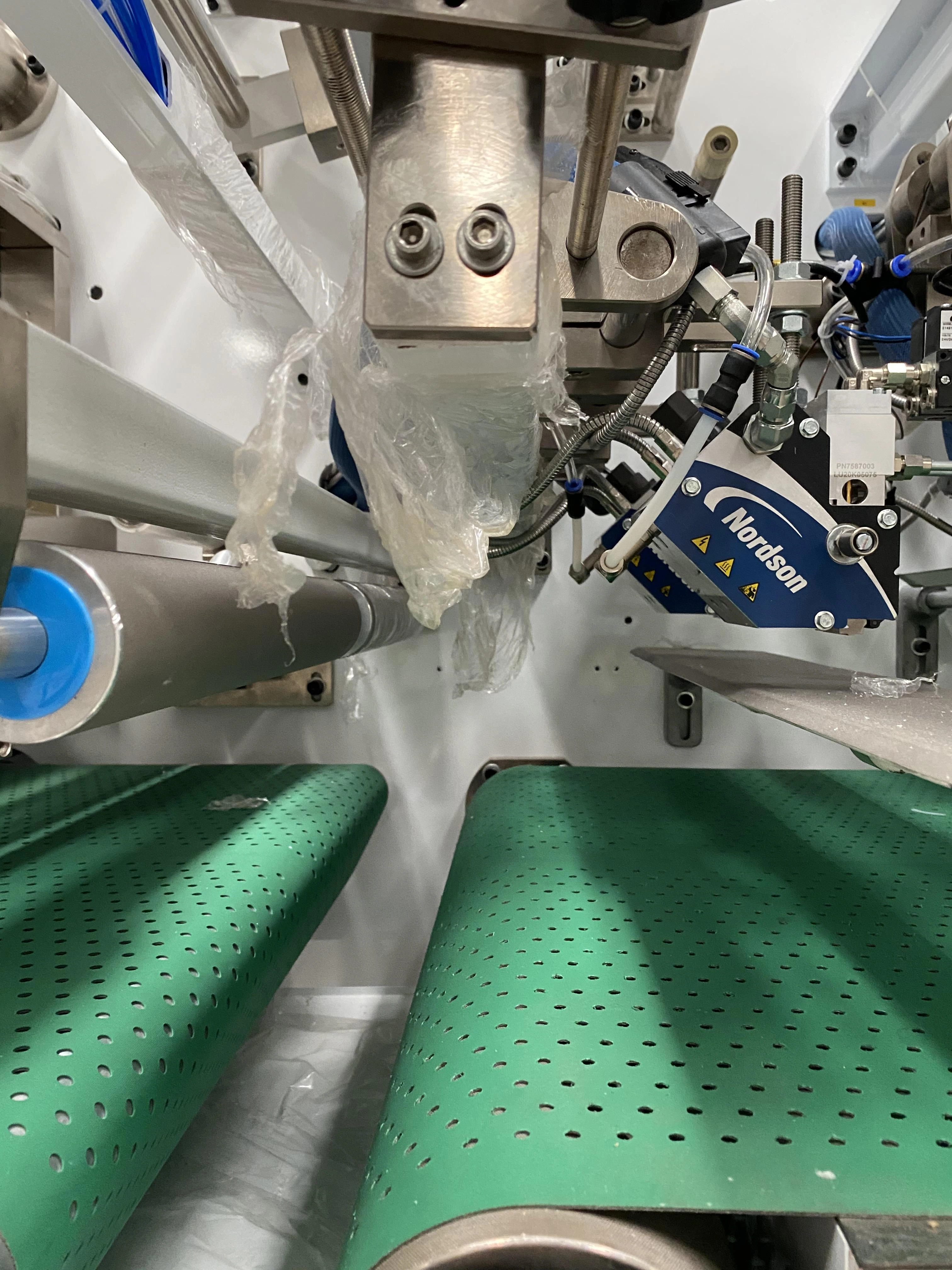

In the coming years, the future of sanitary napkin machinery and equipment is likely to be driven by several key trends. One of the most prominent is the increasing demand for automation and intelligent technology. With the rise of Industry 4.0, manufacturers are looking for ways to streamline their production processes and improve efficiency. Sanitary napkin machinery is no exception. Automated production lines equipped with sensors, robotics, and artificial intelligence can monitor and adjust production parameters in real-time, ensuring consistent quality and reducing waste.

For example, intelligent sensors can detect defects in the raw materials or finished products and trigger alerts for immediate corrective action. Robotic arms can handle delicate materials and perform precise operations, reducing the risk of human error. Artificial intelligence algorithms can analyze production data to optimize machine settings and predict maintenance needs, minimizing downtime and maximizing productivity.

Another trend that is set to shape the future of sanitary napkin machinery and equipment is the focus on sustainability. As consumers become more environmentally conscious, there is a growing demand for eco-friendly sanitary products. This has led to the development of machinery and equipment that can produce sanitary napkins using sustainable materials and processes.

For instance, machines that can process biodegradable materials such as bamboo fiber or recycled plastics are becoming more popular. These materials not only reduce the environmental impact of sanitary napkins but also offer unique properties such as softness, absorbency, and breathability. Additionally, machinery that uses energy-efficient technologies and recycles waste materials is being developed to minimize the carbon footprint of production.

The trend towards customization and personalization is also gaining momentum in the sanitary napkin industry. Consumers are looking for products that meet their specific needs and preferences, and this is driving the development of machinery that can produce customized sanitary napkins.

With advanced printing and packaging technologies, manufacturers can now offer personalized designs, sizes, and absorbency levels. For example, machines can be programmed to print unique patterns or logos on sanitary napkins, or to produce different sizes and shapes to fit individual body types. This level of customization not only enhances the user experience but also gives manufacturers a competitive edge in the market.

Furthermore, the future of sanitary napkin machinery and equipment is likely to see increased collaboration between manufacturers and technology providers. As the industry becomes more complex and competitive, companies are realizing the importance of partnering with experts in different fields to drive innovation.

For instance, WellDone may collaborate with software developers to create advanced production management systems that integrate with their machinery. These systems can provide real-time data on production status, inventory levels, and quality control, enabling better decision-making and operational efficiency. Additionally, partnerships with material suppliers can lead to the development of new and innovative raw materials that can enhance the performance and sustainability of sanitary napkins.

In conclusion, the future of sanitary napkin machinery and equipment is bright and full of possibilities. With the drive towards automation, sustainability, customization, and collaboration, the industry is poised for significant growth and innovation. WellDone, as a leader in the hygiene products and raw materials sector, is well-positioned to lead the way in this evolution. By continuously investing in research and development, embracing new technologies, and listening to the needs of consumers, WellDone can ensure that its machinery and equipment remain at the cutting edge of the industry, shaping the future of sanitary napkins for years to come.

In the coming years, the future of sanitary napkin machinery and equipment is likely to be driven by several key trends. One of the most prominent is the increasing demand for automation and intelligent technology. With the rise of Industry 4.0, manufacturers are looking for ways to streamline their production processes and improve efficiency. Sanitary napkin machinery is no exception. Automated production lines equipped with sensors, robotics, and artificial intelligence can monitor and adjust production parameters in real-time, ensuring consistent quality and reducing waste.

For example, intelligent sensors can detect defects in the raw materials or finished products and trigger alerts for immediate corrective action. Robotic arms can handle delicate materials and perform precise operations, reducing the risk of human error. Artificial intelligence algorithms can analyze production data to optimize machine settings and predict maintenance needs, minimizing downtime and maximizing productivity.

Another trend that is set to shape the future of sanitary napkin machinery and equipment is the focus on sustainability. As consumers become more environmentally conscious, there is a growing demand for eco-friendly sanitary products. This has led to the development of machinery and equipment that can produce sanitary napkins using sustainable materials and processes.

For instance, machines that can process biodegradable materials such as bamboo fiber or recycled plastics are becoming more popular. These materials not only reduce the environmental impact of sanitary napkins but also offer unique properties such as softness, absorbency, and breathability. Additionally, machinery that uses energy-efficient technologies and recycles waste materials is being developed to minimize the carbon footprint of production.

The trend towards customization and personalization is also gaining momentum in the sanitary napkin industry. Consumers are looking for products that meet their specific needs and preferences, and this is driving the development of machinery that can produce customized sanitary napkins.

With advanced printing and packaging technologies, manufacturers can now offer personalized designs, sizes, and absorbency levels. For example, machines can be programmed to print unique patterns or logos on sanitary napkins, or to produce different sizes and shapes to fit individual body types. This level of customization not only enhances the user experience but also gives manufacturers a competitive edge in the market.

Furthermore, the future of sanitary napkin machinery and equipment is likely to see increased collaboration between manufacturers and technology providers. As the industry becomes more complex and competitive, companies are realizing the importance of partnering with experts in different fields to drive innovation.

For instance, WellDone may collaborate with software developers to create advanced production management systems that integrate with their machinery. These systems can provide real-time data on production status, inventory levels, and quality control, enabling better decision-making and operational efficiency. Additionally, partnerships with material suppliers can lead to the development of new and innovative raw materials that can enhance the performance and sustainability of sanitary napkins.

In conclusion, the future of sanitary napkin machinery and equipment is bright and full of possibilities. With the drive towards automation, sustainability, customization, and collaboration, the industry is poised for significant growth and innovation. WellDone, as a leader in the hygiene products and raw materials sector, is well-positioned to lead the way in this evolution. By continuously investing in research and development, embracing new technologies, and listening to the needs of consumers, WellDone can ensure that its machinery and equipment remain at the cutting edge of the industry, shaping the future of sanitary napkins for years to come.

Share

Contact Us

Your email address will not be published. Required fields are marked*

Article Summary

Indian customers

SEARCH

News CATEGORIES

Latest News

Sanitary products OEM factory: practical strategies to reduce brand owners' inventory pressure by 30%

Tuesday 15, 25

Medical Channel Access Guide: List of 12 Qualification Documents Required from OEM Factories

Tuesday 15, 25

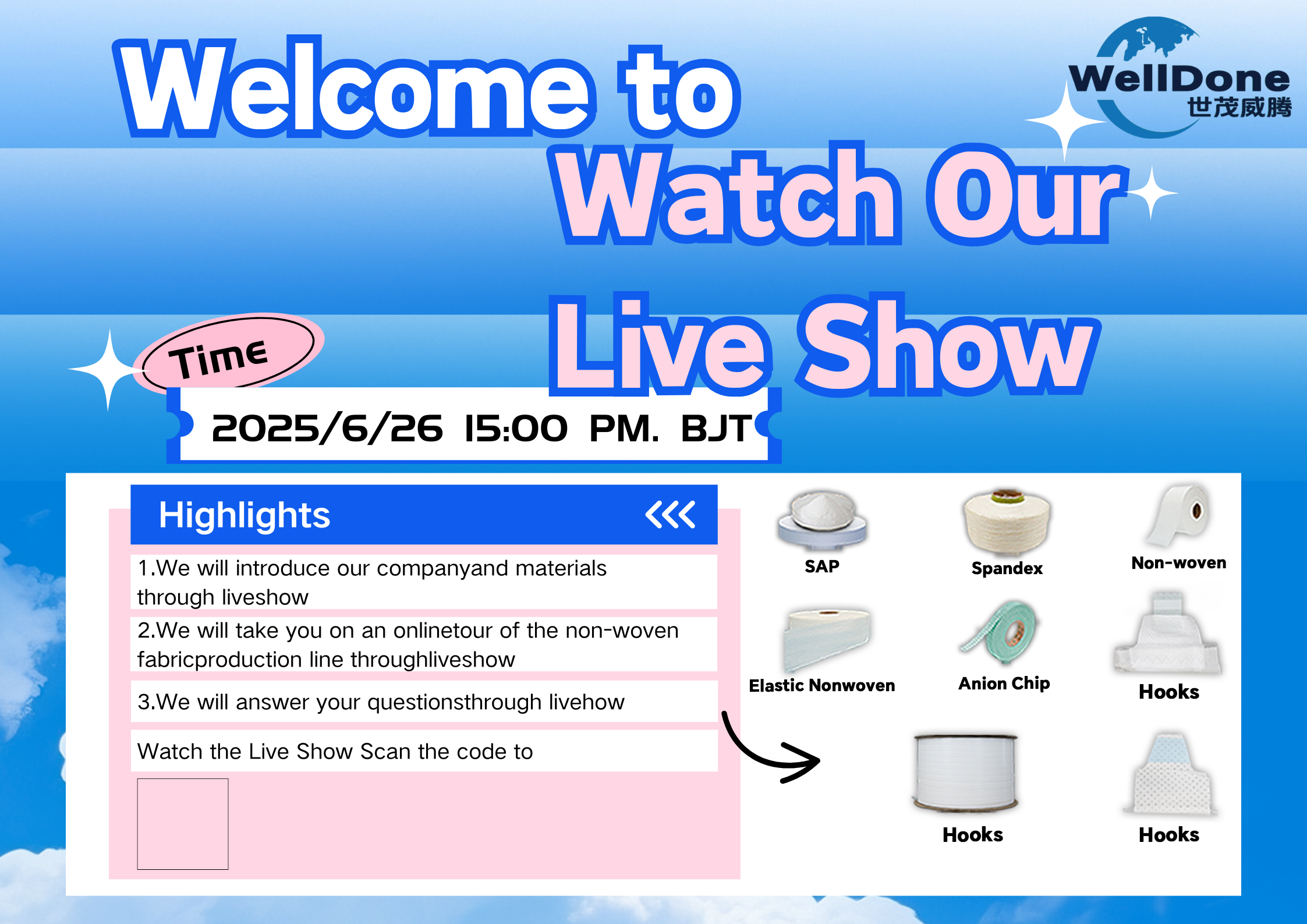

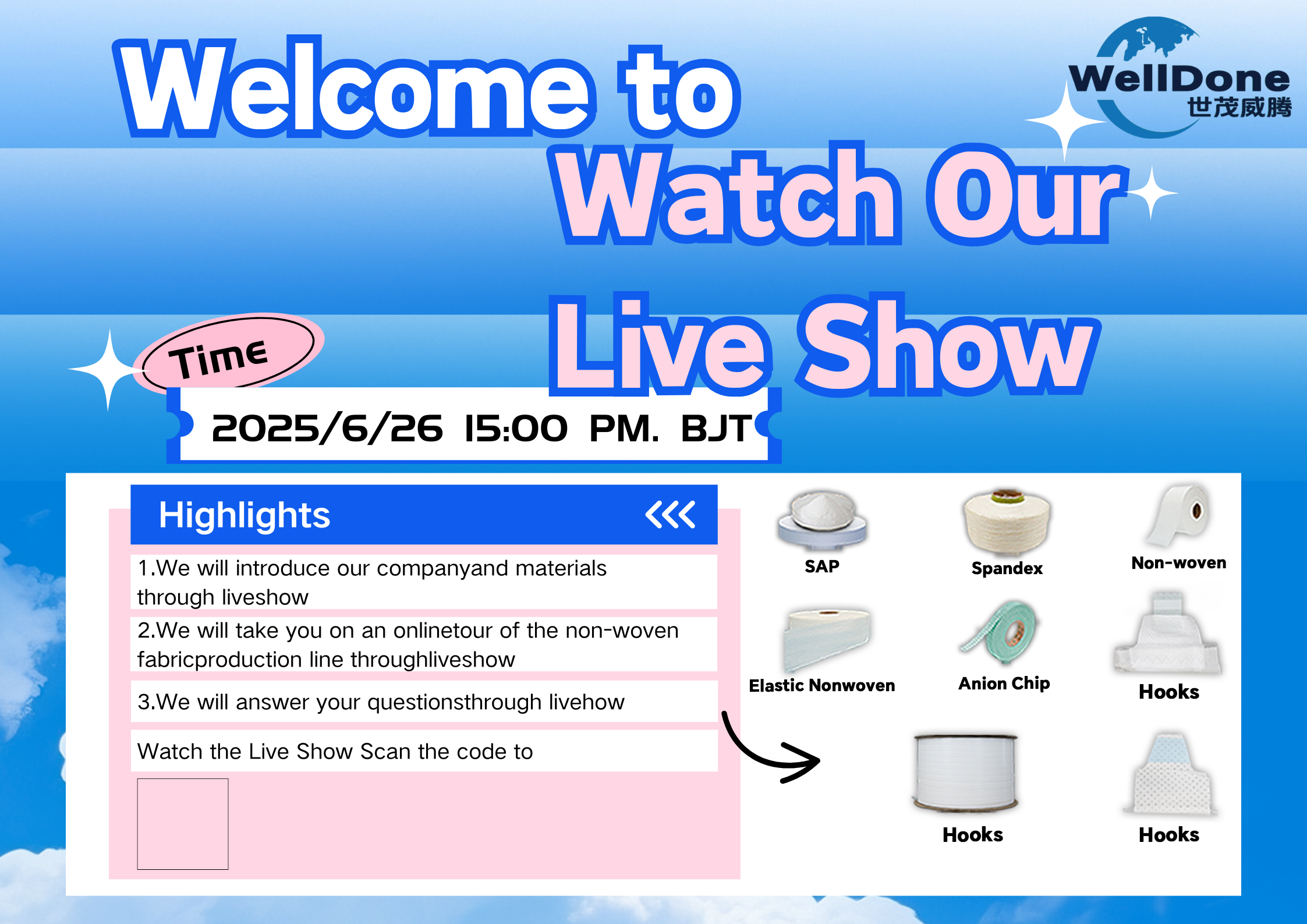

🔴 Join Our Live Show – Explore Hygiene Materials with Welldone!

Wednesday 25, 25

Related News

15

Jul

Company News

·

286

Views

Sanitary products OEM factory: practical strategies to reduce brand owners' inventory pressure by 30%

WELLDONE, as a sanitary products OEM factory with 15 years of experience, helps brands reduce 30% inventory pressure through flexible production, raw material reserves and expedited response, and provides professional OEM/ODM solutions.

15

Jul

Product News

·

390

Views

Medical Channel Access Guide: List of 12 Qualification Documents Required from OEM Factories

This article details the 12 qualification documents required from OEM factories for medical channel access, presented by WELLDONE with 15 years of experience, helping brands select compliant sanitary napkin raw material and machinery OEM factories to quickly enter the medical market.

25

Jun

Company News

·

403

Views

🔴 Join Our Live Show – Explore Hygiene Materials with Welldone!

🗓 Date: June 26, 2025🕒 Time: 3:00 PM (Beijing Time)📍 Live Link: Click here to watch

✨ What

WHAT DO WE DO

OEM Solution

ODM Solution

Hygiene Products Raw Materials Solutions

WellDone is here to solve your hygiene products raw materials woes. With years of experience and a strong network of trusted suppliers, we offer a comprehensive range of high-quality raw materials specifically designed for hygiene product manufacturing.

Raw Materials OEM Solution Processing

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

website link

All Products

PHONE/WHATSAPP/WECHAT:

+86-18350799991 / 18659800016/86-18859717183

TEL:

+86 595-28082887

OFFICE ADD:

NO.1003-1005, Tower A, Wanda Plaza, No.888 Century Avenue, Jinjiang City, Fujian Province, P.R.China

E-MAIL:

welldone@cnwelldone.com

© 2024 WellDone Co., Ltd. | Powered by Matchpages

Privacy Policy

Sitemap

Contact Us