WELLDONE has set a benchmark in the hygiene equipment industry by seamlessly blending cutting-edge technology with unparalleled craftsmanship. Every machine that leaves its production line is a masterpiece of innovation and precision, meticulously designed to meet the highest standards of quality and performance. This article takes an in-depth look at the processes, technologies, and human ingenuity that define WELLDONE’s manufacturing excellence.

A Vision of Precision: The Foundation of WELLDONE’s Production Line

At the heart of WELLDONE’s operations is a commitment to precision manufacturing. The production line is engineered to minimize errors and optimize efficiency, ensuring every machine produced meets exacting specifications. This foundation allows WELLDONE to maintain a reputation for reliability and consistency in its products.

State-of-the-Art Technology: Redefining Industry Standards

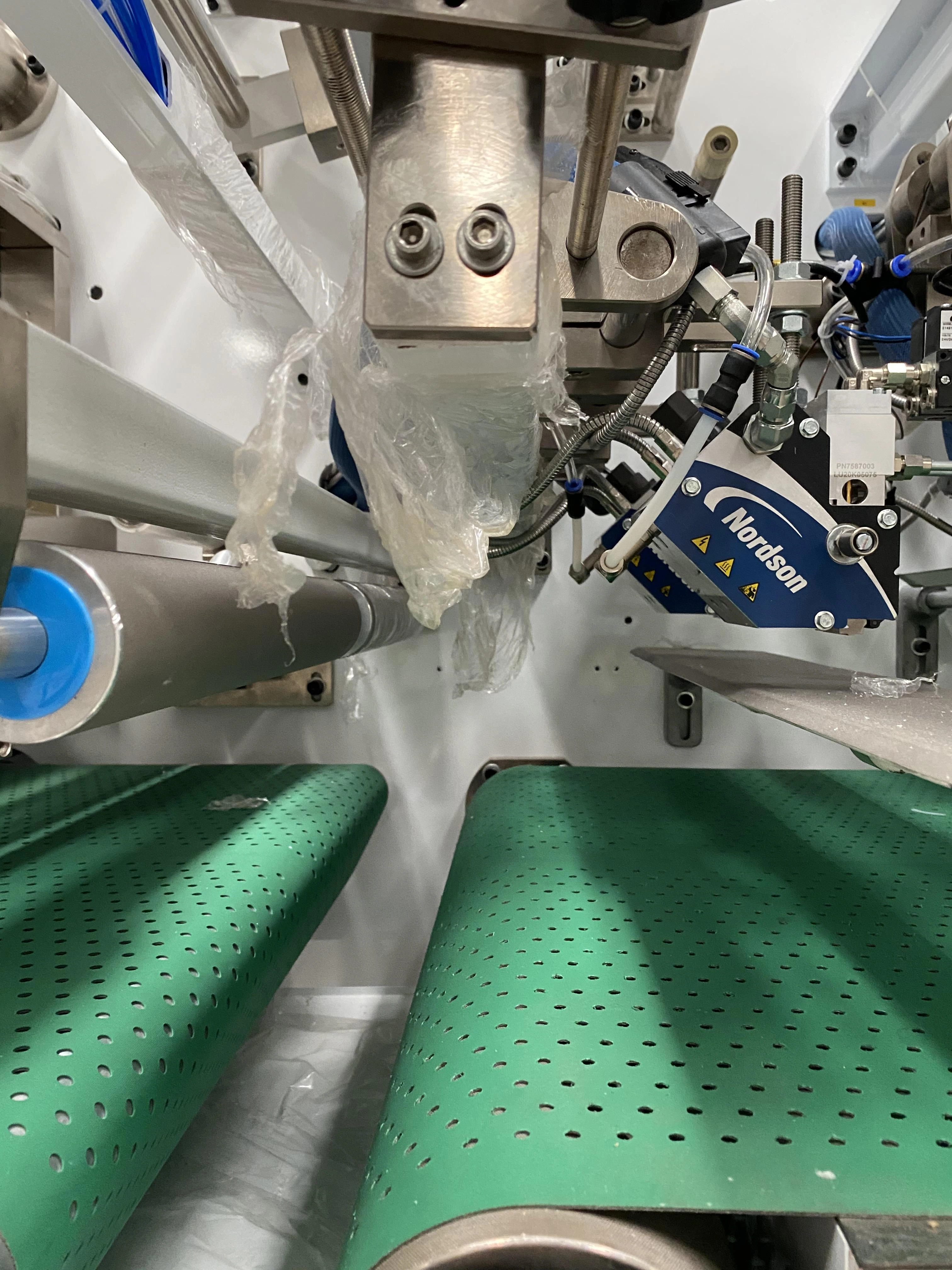

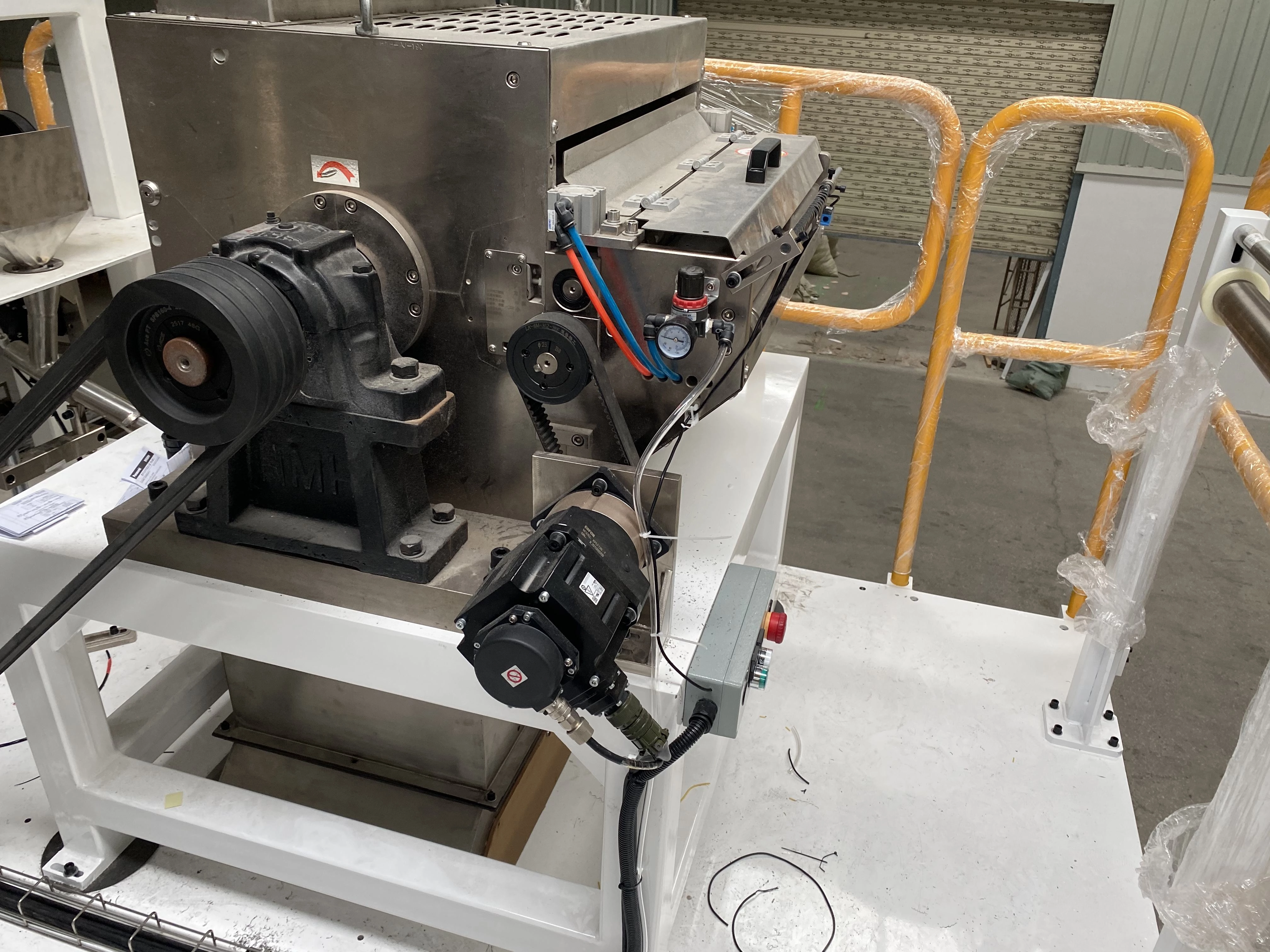

WELLDONE’s production line is a testament to the transformative power of technology. The integration of advanced manufacturing systems, robotics, and artificial intelligence ensures that every component is crafted with unparalleled accuracy.

- Automated Precision: Robotic arms equipped with laser-guided systems handle tasks such as welding, assembly, and material handling, achieving micrometer-level precision.

- Smart Manufacturing: AI-powered monitoring systems oversee every stage of production, identifying and correcting anomalies in real time.

- 3D Printing: Rapid prototyping and production of custom components are enabled by advanced 3D printing technology, reducing lead times and enhancing flexibility.

Human Craftsmanship: The Art of Perfection

While technology drives efficiency, human expertise infuses WELLDONE machinery with a touch of artistry. Skilled engineers and technicians oversee every step of the process, ensuring that each machine is built with care and attention to detail.

- Hand-Finished Excellence: Critical components are hand-finished to achieve seamless integration and optimal functionality.

- Expert Calibration: Precision tools are used to calibrate machines to ensure peak performance under various operating conditions.

- Rigorous Testing: Each machine undergoes thorough testing by seasoned professionals to guarantee compliance with industry standards.

Materials Science Meets Engineering: The Key to Durability

WELLDONE’s production line isn’t just about building machines; it’s about building machines that last. Advanced materials science plays a crucial role in ensuring durability and performance. Stainless steel, high-performance alloys, and advanced polymers are carefully selected and processed to withstand the rigors of industrial use.

- Heat Treatment: Components are heat-treated to enhance strength and resistance to wear.

- Corrosion Protection: Cutting-edge coating technologies protect materials from environmental factors, extending the lifespan of each machine.

- Seamless Integration: Material properties are meticulously matched to ensure compatibility and durability across all components.

Sustainable Manufacturing: A Greener Future with WELLDONE

Sustainability is at the core of WELLDONE’s production philosophy. The company employs eco-friendly practices throughout its manufacturing processes to reduce environmental impact.

- Energy Efficiency: Production lines are powered by energy-efficient systems, minimizing carbon emissions.

- Material Optimization: Waste reduction initiatives, such as recycling scrap materials, ensure that resources are utilized responsibly.

- Eco-Conscious Design: Machines are designed to be energy-efficient in operation, contributing to sustainability across their lifecycle.

Continuous Improvement: Innovation in Action

WELLDONE’s production line is a dynamic ecosystem of constant improvement. Through investment in research and development, the company stays ahead of industry trends, adopting emerging technologies and refining its manufacturing techniques.

- Data-Driven Insights: Real-time data analytics enable WELLDONE to identify inefficiencies and implement improvements rapidly.

- Collaboration with Experts: Partnerships with universities and research institutions foster innovation in materials, processes, and design.

- Customer Feedback Loop: Input from customers drives enhancements in machine functionality and reliability.

From Concept to Completion: A Seamless Journey

WELLDONE’s production process is a seamless journey from concept to completion. Every stage—design, prototyping, manufacturing, assembly, and quality control—is meticulously planned and executed. This end-to-end approach ensures that every machine embodies WELLDONE’s core values of quality, reliability, and innovation.

WELLDONE’s production line is a harmonious blend of cutting-edge technology and time-honored craftsmanship. By investing in state-of-the-art systems and nurturing the expertise of its workforce, WELLDONE creates hygiene equipment that stands as a benchmark of excellence.

Whether it’s the precision of automated robotics or the meticulous hand-finishing by skilled artisans, every detail reflects WELLDONE’s dedication to perfection. As the company continues to innovate and evolve, its production line remains a shining example of how technology and craftsmanship can coexist to redefine industry standards.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.