When it comes to manufacturing hygiene products, the choice of materials is crucial. Every machine component and raw material directly affects the quality of the final product as well as the efficiency of production. WELLDONE Machine Co., Ltd. understands this principle thoroughly, which is why they meticulously select every material used in the design and manufacture of their hygiene product machines. Whether it's equipment used to produce baby diapers, adult diapers, sanitary napkins, or wet wipes, WELLDONE always adheres to high standards when selecting materials to ensure that their machines maintain excellent performance over the long term.

- Key Factors in Material Selection

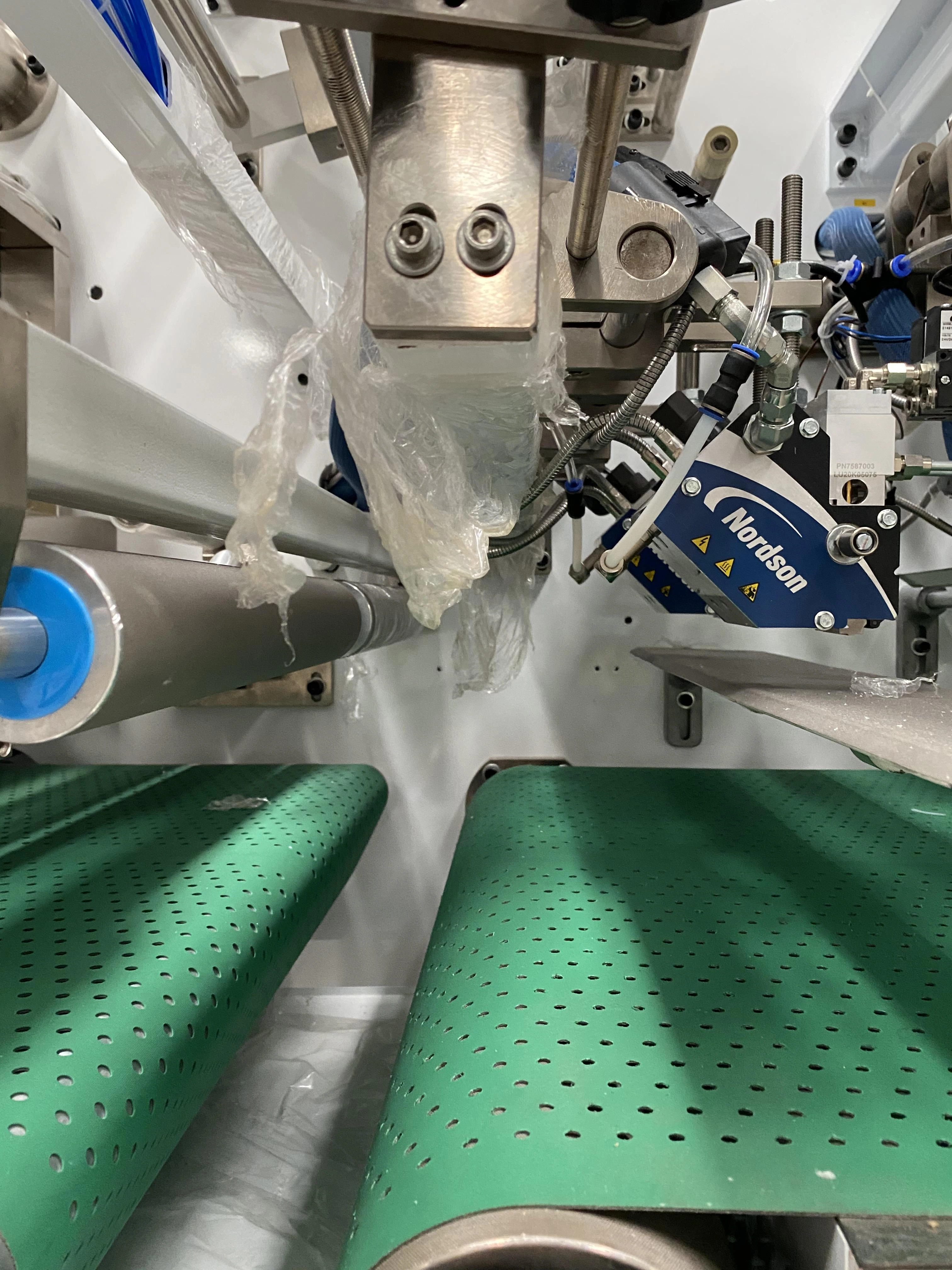

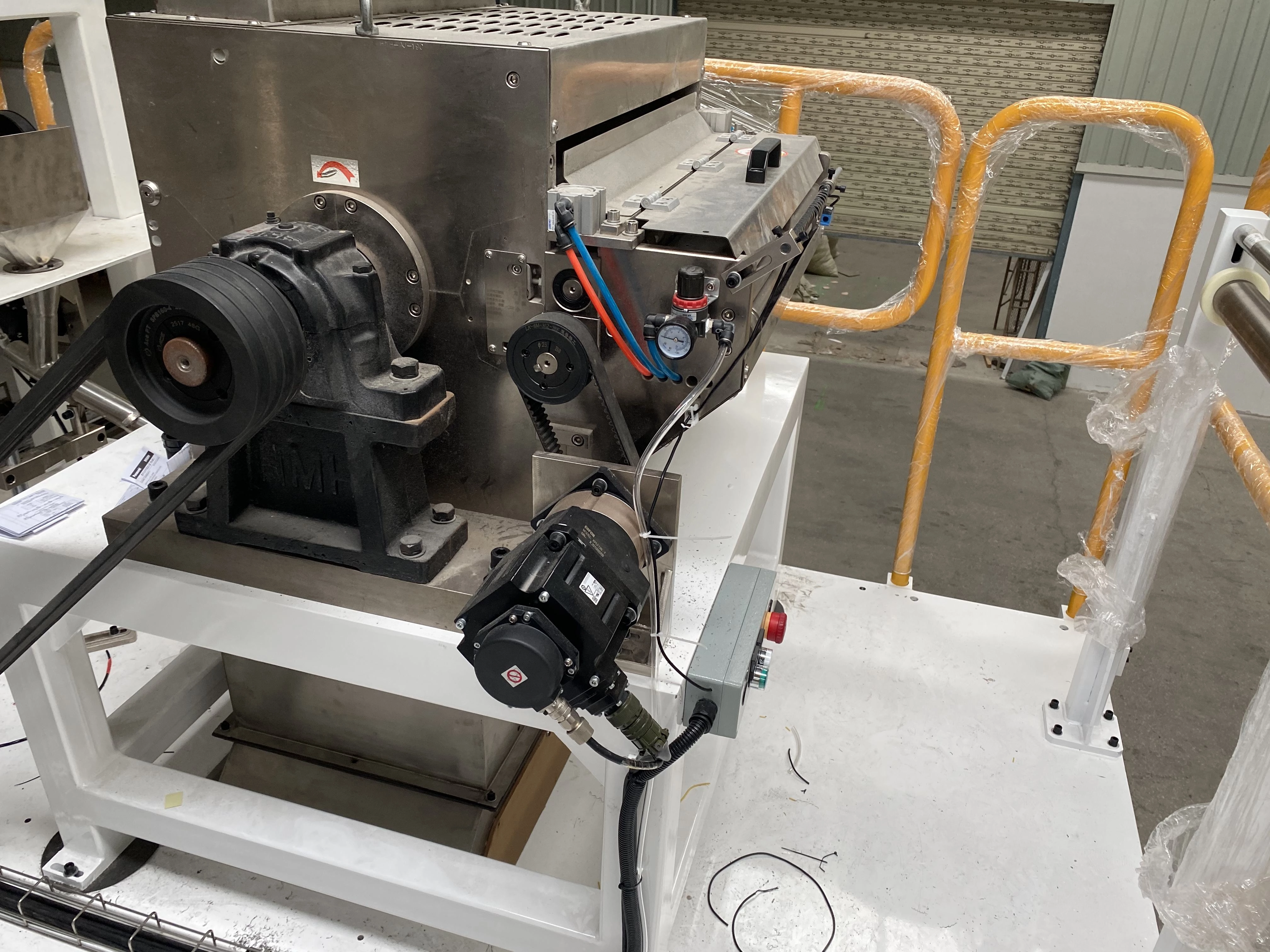

WELLDONE focuses on durability and performance when selecting materials for its machinery. Equipment in hygiene product manufacturing lines operates under high pressure and continuous use, which means every key component—such as gears, bearings, and drive systems—needs to be made of high-strength steel or special alloys. These materials can withstand heavy loads and extended usage, reducing machine breakdowns and downtime.

In addition, WELLDONE places a great emphasis on corrosion resistance. During the manufacturing process of hygiene products, machines are frequently exposed to moisture and chemicals, making rust-resistant materials like stainless steel a must. These materials ensure the long-term stability of the equipment and prevent bacterial growth caused by corrosion. This is particularly important in machines used for manufacturing wet wipes, sanitary pads, and other hygiene products, where maintaining a sterile environment is critical.

- Sustainability and Eco-friendly Material Selection

In its material selection process, WELLDONE also pays close attention to sustainability and environmental impact. As a responsible company, WELLDONE is committed to reducing the environmental footprint of its manufacturing processes. By choosing eco-friendly materials and green manufacturing methods, WELLDONE aims to ensure the sustainable use of resources. For instance, WELLDONE has redesigned some of its parts and components to utilize more environmentally friendly alternatives, which not only reduce the environmental impact but also improve production efficiency.

Moreover, WELLDONE prioritizes the use of recyclable materials to minimize waste and lower production costs. This initiative supports the company’s efforts to reduce harmful emissions during manufacturing and adhere to global sustainability standards. The focus on eco-friendly materials ensures that the company’s production lines are aligned with both industry regulations and the growing demand for environmentally responsible manufacturing practices.

- Precision Engineering for Consistent Quality

The precision in selecting materials extends beyond simply choosing durable and environmentally friendly options. WELLDONE machines are known for their precision engineering, ensuring consistent product quality. Whether it’s the non-woven fabric used in diapers or the specialized components in a wet wipe machine, WELLDONE ensures that every material meets strict specifications. This high level of quality control is key to achieving consistent results in the production of hygiene products, which is critical for B2B clients who rely on machines for large-scale production.

By leveraging advanced engineering techniques and material science, WELLDONE is able to deliver machines that consistently produce high-quality products, thereby helping its clients meet the ever-increasing demands of the hygiene product market. The ability to maintain consistent production quality also ensures that clients can minimize waste and maximize efficiency.

- Collaboration with Leading Material Suppliers

To ensure the highest quality of materials, WELLDONE collaborates closely with leading material suppliers worldwide. These suppliers provide the company with access to the latest innovations in material technology, ensuring that their machines are always made with the best available components. WELLDONE’s strong relationships with these suppliers allow for a continuous supply of premium materials, even as industry standards evolve. This collaboration is vital for keeping WELLDONE’s machines on the cutting edge of performance and durability.

The company also works closely with material experts to source and test new materials that can improve the efficiency and sustainability of their machines. By staying ahead of material trends and technology, WELLDONE ensures that its products remain at the forefront of the hygiene product manufacturing industry.

- Long-term Investment in Material Quality

At WELLDONE, material selection is not just about short-term gains but also long-term investment. The company understands that the durability and reliability of its machinery depend on the quality of the materials used in their construction. By investing in high-quality materials from the outset, WELLDONE ensures that its machines provide maximum value over their operational lifespan. This approach reduces the need for costly repairs or replacements, offering long-term savings to clients.

By focusing on premium materials, WELLDONE not only guarantees the performance and longevity of its machines but also enhances the overall value proposition for its clients. This commitment to quality ensures that businesses relying on WELLDONE machines can achieve consistent production results with minimal downtime and maintenance costs.

Conclusion

The meticulous selection of premium materials is at the heart of WELLDONE’s philosophy in designing and manufacturing hygiene product machines. From durability and corrosion resistance to sustainability and precision engineering, every aspect of material selection is carefully considered to ensure that the machines meet the highest standards of performance and reliability. By collaborating with top material suppliers and focusing on long-term investment in quality, WELLDONE continues to lead the industry in producing high-quality, efficient, and environmentally responsible machines for hygiene product manufacturing.

This commitment to superior materials not only elevates WELLDONE’s machines but also ensures that their customers, both globally and locally, can rely on state-of-the-art technology to meet the growing demands of the hygiene industry.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.