In the competitive world of hygiene product manufacturing, quality control is essential for success. Whether it is the production of baby diapers, sanitary napkins, or adult incontinence products, ensuring that every step of the manufacturing process meets the highest standards is a critical part of achieving product excellence. WELLDONE Machine Co., Ltd. has long been recognized for its commitment to defining high standards in production, from the selection of raw materials to the creation of state-of-the-art machines.

WELLDONE has built its reputation as a leader in the hygiene product machinery sector by maintaining stringent quality standards throughout the entire production process. The company’s emphasis on using top-tier raw materials, advanced engineering practices, and rigorous quality control processes ensures that its machines operate with precision, efficiency, and reliability.

-

Selecting the Best Raw Materials for Optimal Performance

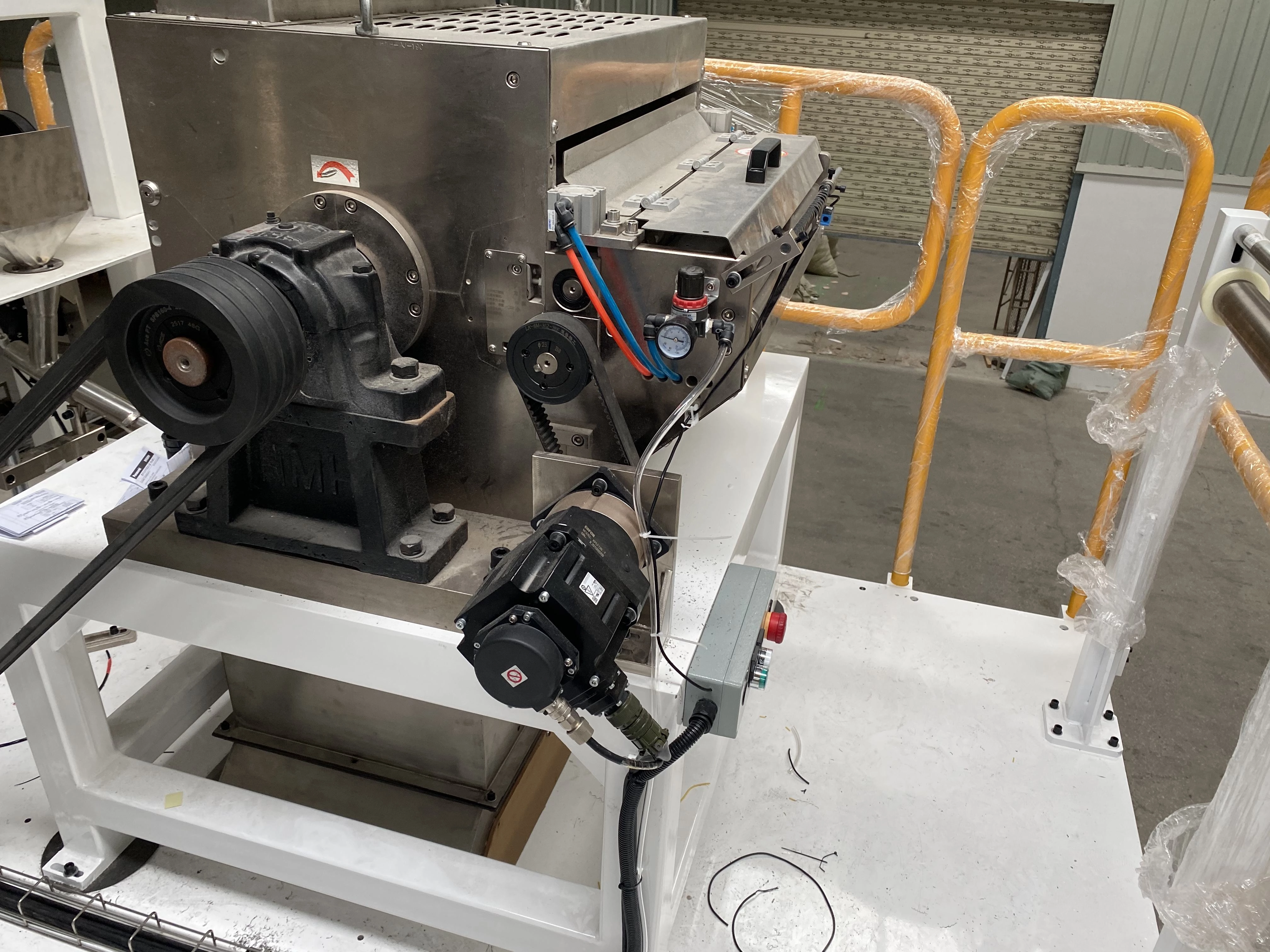

The foundation of any great machine starts with its raw materials. WELLDONE places a strong emphasis on selecting high-quality materials that will ensure the durability, efficiency, and reliability of its machinery. Materials like premium-grade stainless steel, high-tensile alloys, and other advanced composites are carefully sourced from trusted suppliers, all of whom adhere to the highest international standards. By starting with the best materials, WELLDONE guarantees that the machines it manufactures will stand up to the rigors of continuous operation in high-demand environments.

Each raw material is thoroughly tested for quality and suitability before it is used in the production of any machine. The quality control team at WELLDONE ensures that the materials meet specific criteria, such as resistance to corrosion, flexibility, and the ability to withstand high-pressure conditions. This careful selection process ensures that every part of the machinery – from small components like gears and screws to larger parts like the machine frame – is capable of performing at the highest level.

-

Engineering Excellence: Designing for Precision

Once the raw materials have been selected, the next step in defining high standards in production is the engineering phase. WELLDONE employs a team of skilled engineers who are experts in designing hygiene product machinery with a focus on precision and performance. Using advanced CAD (Computer-Aided Design) software, the engineering team creates detailed blueprints for each machine, ensuring that every component fits together seamlessly.

The design process takes into account a variety of factors, including the machine’s intended application, production speed, ease of maintenance, and energy efficiency. WELLDONE’s engineers work closely with customers to understand their specific needs and tailor designs to meet those requirements. Whether the customer needs a high-speed diaper production line or a more specialized sanitary napkin machine, WELLDONE’s engineers ensure that each design maximizes productivity while maintaining the highest standards of quality and precision.

-

Rigorous Testing and Quality Control

Testing and quality control are at the heart of WELLDONE’s production process. Before any machine is delivered to a client, it undergoes a series of rigorous tests to ensure that it meets the company’s high standards. These tests include functional testing, stress testing, and performance evaluations to ensure that every component of the machine operates smoothly and efficiently. For example, WELLDONE's diaper-making machines undergo extensive trials to ensure that the finished diapers meet the required quality standards in terms of absorbency, comfort, and durability.

The testing process also includes evaluations of machine longevity and safety. WELLDONE’s team ensures that the machines are built to last and that all safety measures are in place to protect operators during production. By running each machine through a series of real-world tests, WELLDONE can identify any potential issues and address them before the equipment reaches the customer.

In addition to functional testing, WELLDONE’s quality control team ensures that the machines adhere to the necessary international standards and certifications. This attention to detail ensures that customers receive equipment that not only meets their specific requirements but also complies with industry regulations.

-

Manufacturing with Precision

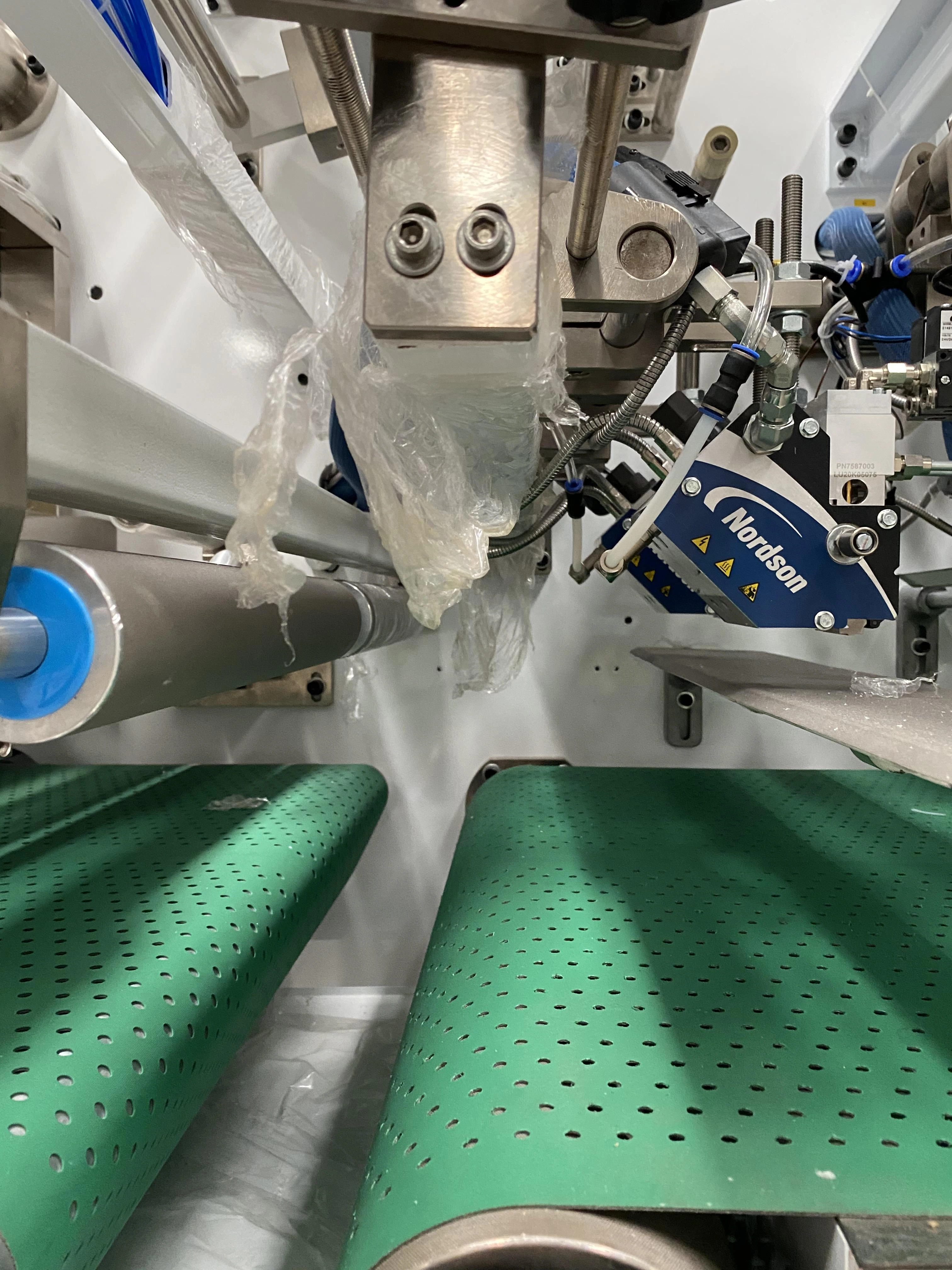

Once the design is finalized and the materials are sourced, the next phase is the actual manufacturing process. WELLDONE uses advanced CNC (Computer Numerical Control) machines, robotics, and other automated technologies to manufacture its machines with unparalleled precision. These machines allow for precise cutting, shaping, and assembling of parts, ensuring that each component is made to exact specifications.

By utilizing automation in the manufacturing process, WELLDONE minimizes human error and ensures that every part is produced with a high degree of accuracy. This allows the company to maintain consistent quality across all of its machines, reducing the likelihood of defects and ensuring that each product is built to last. Additionally, the use of robotics allows for faster production times, ensuring that WELLDONE can meet the growing demand for its machines while maintaining high standards.

-

Customization for Specific Client Needs

While WELLDONE’s commitment to high standards is evident in every machine it manufactures, the company also understands that each customer has unique needs. As such, WELLDONE offers customization options for its hygiene product machines, allowing customers to tailor the machines to their specific requirements. Whether it is adjusting the speed of production, modifying the size or shape of the equipment, or incorporating additional features for automation, WELLDONE works closely with customers to ensure that the machines meet their exact specifications.

This level of customization requires careful collaboration between the client and WELLDONE’s design and engineering teams. By understanding the specific goals and constraints of each client, WELLDONE is able to produce machinery that fits seamlessly into their production process, enhancing efficiency and improving overall output.

-

Continuous Innovation and Improvement

To maintain its position as an industry leader, WELLDONE is committed to continuous innovation and improvement. The company is always looking for ways to enhance its machinery and manufacturing processes to meet the ever-changing demands of the hygiene product market. By staying ahead of industry trends and integrating emerging technologies into its machines, WELLDONE ensures that its equipment remains at the cutting edge of performance and efficiency.

WELLDONE regularly invests in research and development to explore new materials, manufacturing techniques, and machine designs. This commitment to innovation allows the company to introduce new features and improvements to its machines, enhancing production efficiency, reducing costs, and ultimately helping clients improve their bottom line.

WELLDONE’s commitment to defining high standards in production is evident in every phase of its manufacturing process. From the careful selection of raw materials to the use of cutting-edge technology and rigorous quality control measures, WELLDONE ensures that every machine meets the highest performance and quality standards. By focusing on precision engineering, customization, and continuous innovation, WELLDONE has become a trusted partner for companies in the hygiene product manufacturing industry, offering reliable, high-quality machines that help businesses achieve their production goals.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.