In the world of hygiene product manufacturing, precision is everything. A single flaw in the production line can result in costly defects, wasted resources, and lost time. WELLDONE Machine Co., Ltd. has mastered the art of precision engineering, which allows the company to provide high-performance machines that consistently meet the stringent requirements of its customers. With a focus on developing equipment that can handle large-scale production while maintaining superior quality, WELLDONE has earned a reputation for its precision-driven manufacturing processes.

-

The Importance of Precision in Hygiene Product Machines

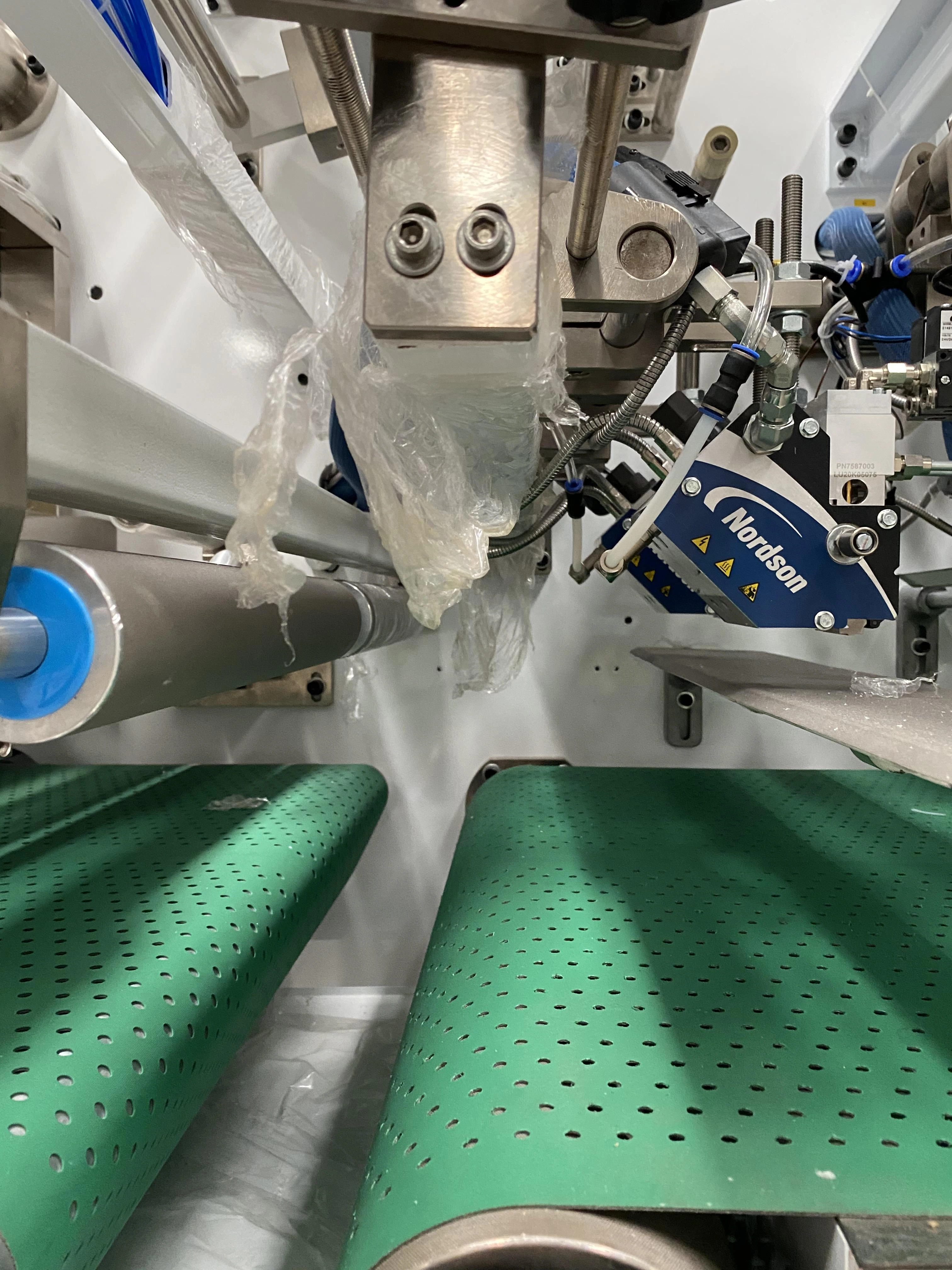

When it comes to manufacturing hygiene products like diapers, sanitary pads, and wet wipes, precision is crucial. These products require delicate handling to ensure proper functionality and comfort. For example, a small mistake in the alignment of the non-woven fabric or an issue with the seal on a diaper can result in an entire batch being rejected. WELLDONE’s commitment to precision ensures that every machine it produces maintains the highest standards of quality, keeping production lines efficient and product quality consistent.

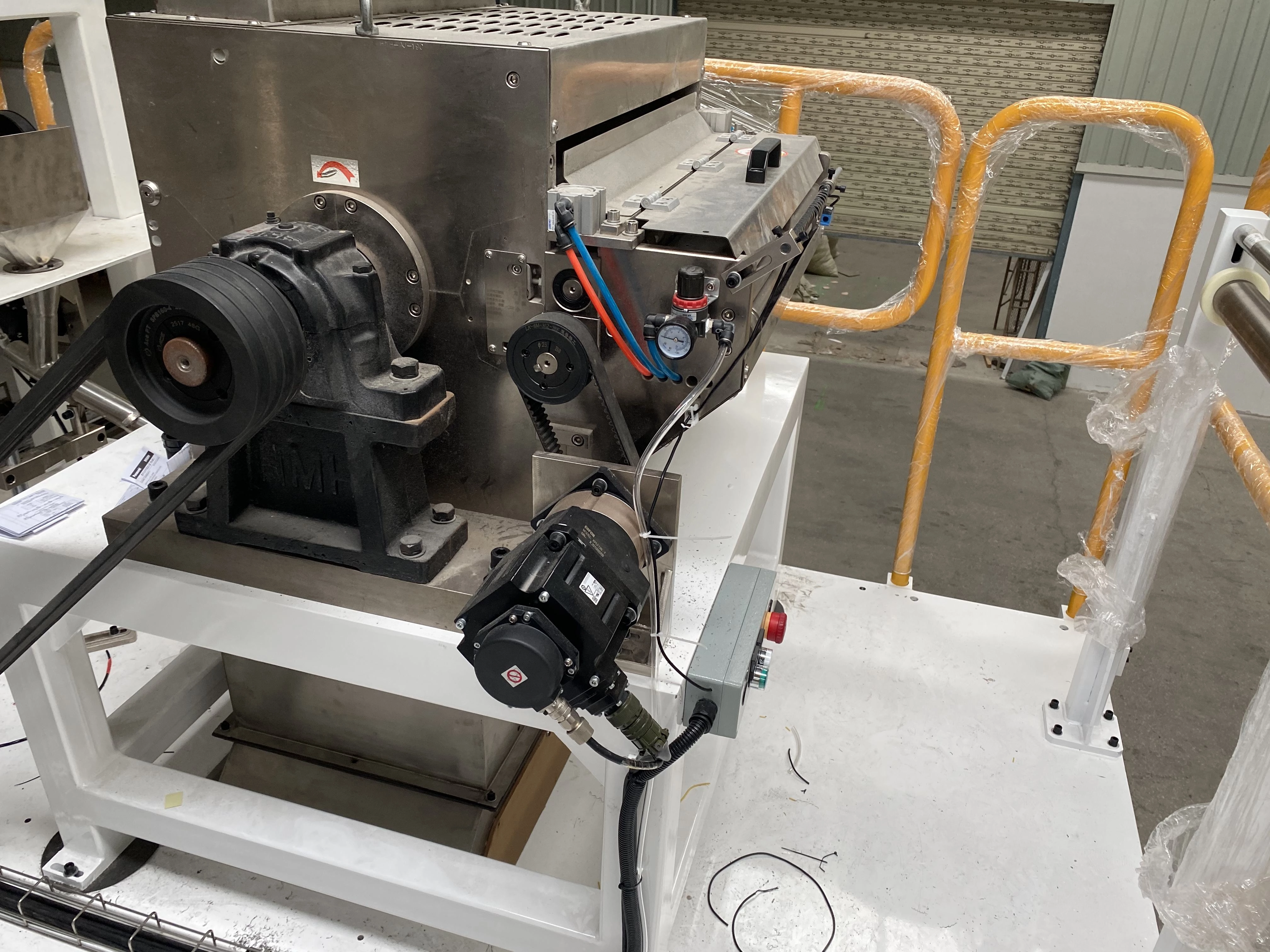

In WELLDONE’s manufacturing process, every component, from the smallest screw to the largest steel frame, must meet exacting specifications. The precision engineering that goes into each machine ensures that these components work seamlessly together, preventing issues such as jams or malfunctions during production. This attention to detail not only enhances the operational efficiency of the machines but also helps to ensure that the final hygiene products are of the highest quality.

-

Advanced Technology for Precision Manufacturing

WELLDONE incorporates advanced technologies into its precision engineering practices. With state-of-the-art CNC (Computer Numerical Control) machinery and 3D printing, WELLDONE is able to produce parts and components that are virtually flawless. CNC machines allow for the precise cutting and shaping of metal components, while 3D printing technology is used for creating prototype parts quickly and accurately. This technology enables WELLDONE to test and refine its designs before moving to full-scale production, ensuring that all components fit together perfectly.

In addition, WELLDONE invests in highly sophisticated inspection equipment, such as laser measurement systems and precision gauges, to ensure that every part meets exact tolerances. These technologies allow WELLDONE to monitor and maintain the highest level of quality control throughout the entire manufacturing process, guaranteeing that each machine functions at peak performance from start to finish.

-

High-Quality Material Selection for Precision Performance

The selection of high-quality materials plays a pivotal role in achieving precision in hygiene product machines. WELLDONE is selective when it comes to sourcing the materials that are used to construct its machines. Components such as gears, bearings, and frames are made from premium-grade alloys and stainless steel, which have been carefully chosen for their ability to withstand the rigors of continuous operation.

Additionally, WELLDONE carefully inspects all materials before they are used in production. This ensures that only the highest quality materials are used in its machines, preventing potential flaws and ensuring that each component functions flawlessly within the larger system. The company’s material selection process is just one part of its overall commitment to precision, ensuring that every machine meets the exact specifications required for optimal performance.

-

Customization and Adaptability

WELLDONE recognizes that every client has unique needs. As such, the company offers customized solutions for its hygiene product machines, enabling clients to adapt the equipment to suit their specific production requirements. Whether it’s modifying the size or shape of the machine, adjusting the production speed, or enhancing the automation level, WELLDONE’s machines can be tailored to deliver the exact results clients need.

This level of customization requires a deep understanding of both the technical aspects of machine design and the specific needs of the client. WELLDONE’s engineering team works closely with clients to ensure that each machine is tailored to their exact specifications, from the choice of materials to the precision of the components. By offering such adaptability, WELLDONE ensures that its clients receive the best possible equipment for their production needs, with machines that deliver consistent, high-quality results.

-

The Role of Experienced Engineers and Technicians

At WELLDONE, precision engineering is a team effort. The company employs a skilled team of engineers and technicians who are experts in the design and construction of hygiene product machinery. These professionals bring years of experience to the table and are constantly refining their knowledge to ensure that WELLDONE’s machines remain at the forefront of technological innovation.

WELLDONE’s engineers play a critical role in ensuring that each machine is designed to operate with the utmost precision. From the initial design phase to final production, engineers use their expertise to guarantee that every part and component is correctly engineered and assembled. Technicians, meanwhile, are responsible for the final checks and tests before the machines are shipped to clients. They conduct rigorous testing to ensure that the machines meet the highest standards of performance and reliability before they leave the factory floor.

-

Continuous Improvement for Enhanced Precision

WELLDONE’s commitment to precision engineering is not a one-time effort. The company is always looking for ways to improve its manufacturing processes and refine its machines. By keeping an eye on emerging technologies and trends in the industry, WELLDONE ensures that its machines are continuously evolving to meet the growing demands of the hygiene product market.

The company’s dedication to continuous improvement extends to every aspect of its operations. From design and material selection to manufacturing and testing, WELLDONE is always striving to enhance the precision of its machines. By constantly innovating and fine-tuning its processes, WELLDONE ensures that its customers always receive the most reliable and efficient machinery available.

WELLDONE’s precision engineering is at the heart of its success in the hygiene product manufacturing industry. By incorporating advanced technology, carefully selecting high-quality materials, and offering customizable solutions, WELLDONE ensures that its machines deliver exceptional performance. The company’s focus on precision helps maintain the efficiency of production lines, minimizes waste, and guarantees the consistent quality of the final products. With a team of skilled engineers and a commitment to continuous improvement, WELLDONE continues to lead the industry in the development of high-performance, precision-driven machines for hygiene product manufacturing.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.