Against the backdrop of the continuous expansion of the global hygiene product market, brand owners are placing higher demands on the quality control capabilities, supply chain response speed, and customized services of OEM factories. According to the "2024 Analysis of the Current Situation and Future Development Trends of the Disposable Hygiene Product Industry," the global market size of disposable hygiene products is expected to exceed $256 billion in 2024. Among them, female care products account for 54.1%, and the growth rate of adult incontinence products reaches 9.8%. With 15 years of industry experience, WELLDONE (Jinjiang, Fujian, China) deeply understands that the core demands of B2B customers are not only production capacity output but also the quality assurance ability throughout the entire R&D, production, and delivery process. This article will deeply analyze the three core competitiveness factors of the hygiene product OEM industry, providing decision-making references for brand owners.

Full-Link Quality Control: Building an International Standard Quality Moat

🌿1. Raw Material Screening: From Molecular-Level Testing to Traceability Management

WELLDONE uses SAP superabsorbent polymers from the world's top 5 suppliers. Its water absorption rate exceeds the industry benchmark by 30%, and it is stored in separate warehouses in an ISO13485 medical device-class dust-free workshop. Each batch of raw materials needs to undergo 12 physical and chemical tests, including core indicators such as formaldehyde residue (<10mg/kg) and pH value (5.5 - 7.0). The test data is uploaded to the MES system in real-time to achieve full-life-cycle traceability.

🎯2. Process Innovation: Solving Industry-Pain-Point Technologies

To address the problem of high backflow rates in baby diapers, WELLDONE has developed a 3D embossed diversion layer technology, which increases the liquid diffusion speed by 40% and makes the surface dryness meet the EU EN14350 standard. In the field of adult incontinence products, it has pioneered the "honeycomb structure" absorbent core, with a unit area bearing capacity of 1.2kg/cm², far exceeding the Japanese JIS L1907 standard.

✔️3. Finished Product Inspection: Establishing a Four-Dimensional Quality Firewall

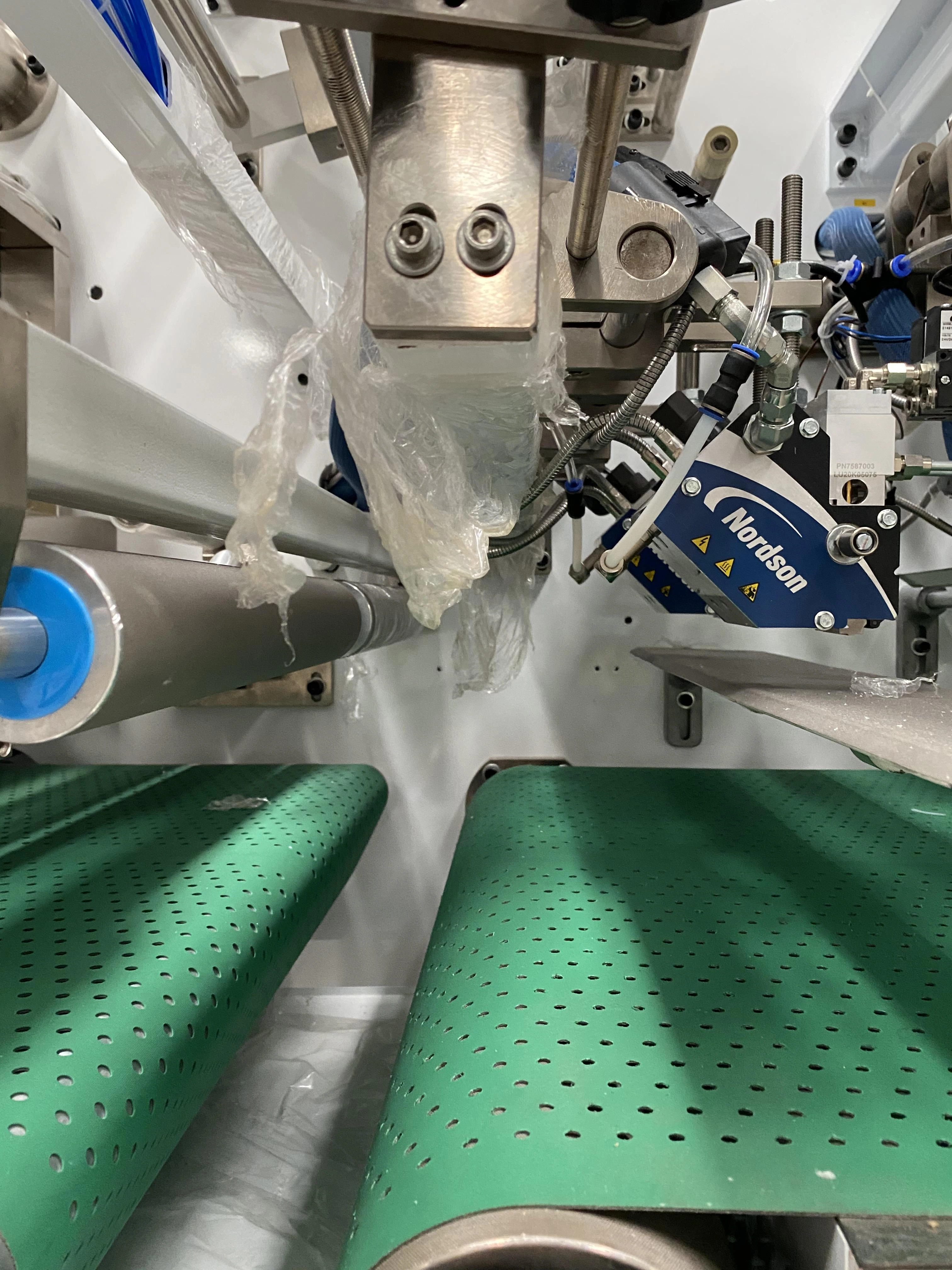

The production line is equipped with an AI vision inspection system that can identify defects such as 0.1mm-level glue offset and fiber clumps, with a defective product interception rate of 99.97%. Before finished products are warehoused, they need to pass seven major verification links, such as the simulated transportation vibration test (ASTM D4169) and the 48-hour constant temperature and humidity stability test (GB/T 28004).

Trend Insights: Seizing the High Ground in Niche Markets

1. The Revolution of Environmentally Friendly Materials

According to the "Southeast Asian Hygiene Product Market Boom" report, the demand for degradable materials in the European and American markets is increasing by 23% annually. WELLDONE has mass-produced PLA polylactic acid sanitary napkin back films with a biodegradation rate of 90% (ASTM D6400), and has reserved 5 new environmentally friendly material solutions such as seaweed fibers and bamboo pulp composite fabrics.

2. Fine-Grained Scenario Segmentation

- Medical-Grade Products: Disinfectant wipes use a quaternary ammonium salt composite formula that meets the EU EN14476 standard, and can inactivate the H1N1 virus with an efficiency of 99.99% within 30 seconds.

- Silver Economy Track: Adult diapers are equipped with intelligent humidity-sensing strips that can be connected to a nursing system via Bluetooth to achieve remote care warnings.

- Hotel Scenario: A 12cm ultra-thin compressed towel has been developed, with a water absorption ratio exceeding 8 times, and the single-pack volume is 60% less than that of traditional products.

3. Regional Customization Strategies

For the high-temperature and high-humidity environment in Southeast Asia, antibacterial sanitary napkins containing tea tree oil ingredients have been developed, with a bacteriostatic rate > 99.4% (GB15979). For the Middle East market, a high-tech cooling pad has been launched, which can cool the body surface by 3 - 5°C within 30 seconds of contact.

B-End Service Enablement: Creating a Brand Growth Engine

1. Flexible Supply Chain System

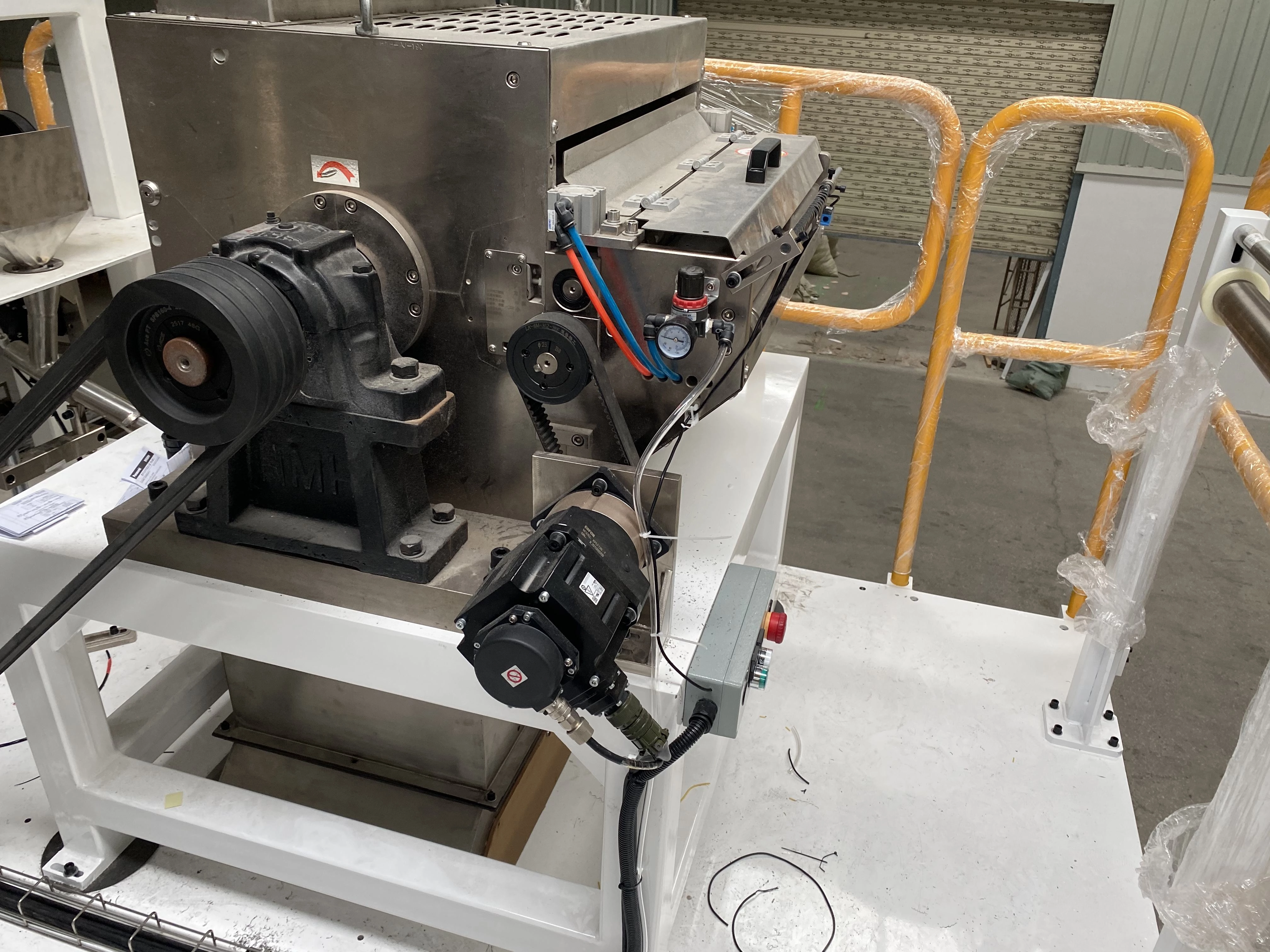

Through the intelligent production scheduling system, samples can be produced within 72 hours, and mass production and delivery can be achieved within 15 days. It supports small-batch customization with a minimum order quantity of 10,000 pieces, helping new brands reduce inventory risks. In 2024, a new production line from KraussMaffei in Germany was added, enabling the daily production capacity of wet wipes to exceed 20 million pieces.

2. Compliance Certification Matrix

WELLDONE has obtained 23 international certifications such as FDA 510(k), CE, and FSC, and can simultaneously meet more than 30 regulatory requirements, including the EU REACH and China's GB/T 8939, helping brands quickly enter the European, American, and RCEP countries' markets.

In conclusion, with its full-link quality control, accurate trend insights, and powerful B - end service enablement, WELLDONE has significant advantages in the hygiene product OEM field. We look forward to collaborating with more brands to expand the global market and bring higher - quality and more diverse hygiene products to consumers.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.

WELLDONE is one of the leading companies, which is focused on supplying A-Z Service for the customer in the disposable hygiene product field, which located in Jinjiang City, Fujian Province, China.